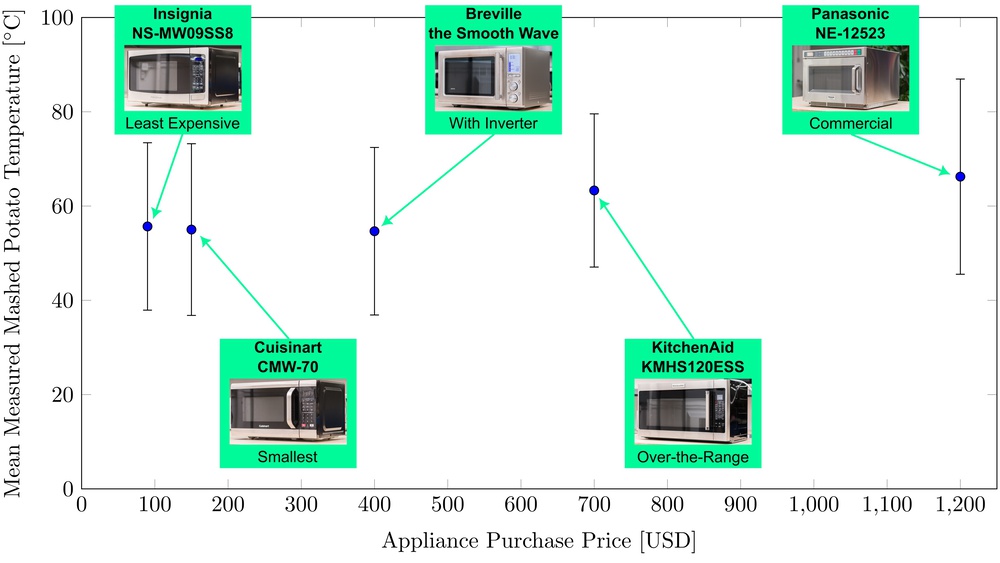

After months of rigorous testing, retesting, and extensive investigation, we concluded that microwave ovens are remarkably similar in performance. We evaluated 26 different models, using standardized methods to measure heating evenness. For shallow dishes, we employed marshmallow "heatmaps" and image analysis. For deep dishes, we used an array of thermocouples to map the 3-dimensional temperature distribution in reheated mashed potatoes. The microwaves produced nearly identical results in every case, with any minor differences attributable to data noise. The following figure presents a representative subset of the mashed potato results. You can see that regardless of purchase price, dimensions, power control, installation type, and build quality, all the appliances have equivalent performance. Further investigations with other foods (white rice, soup) and food analogs (polycarbonate) revealed why all the microwaves have the same heating performance. The food's characteristics—amount, shape, water content, and thermal properties—dictate the heating outcomes rather than the microwave itself.

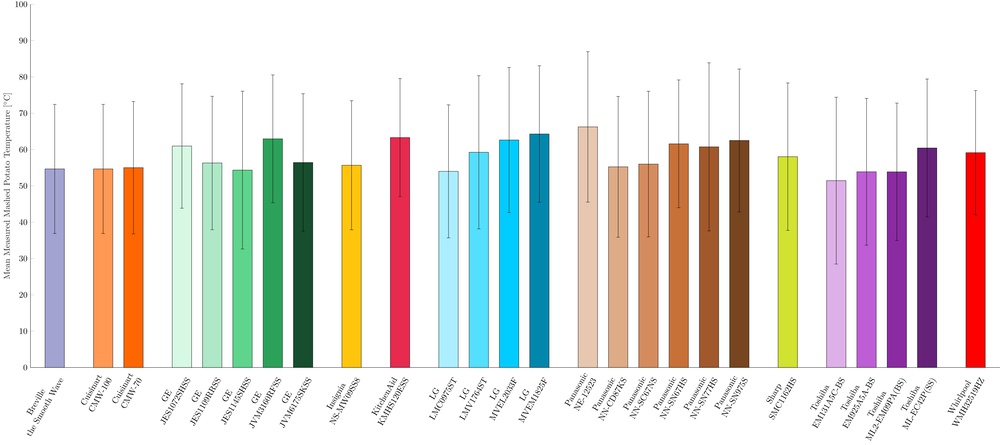

A representative subset of the measured mashed potato temperature data. Here, we plot the mean temperatures versus purchase price for the range of microwave types we tested in this batch. Error bars represent standard deviations on the mean. All the microwaves have the same heating performance.

Given these results, we've opted not to include heating evenness performance scores in our microwave reviews. Despite our efforts to distinguish between models based on heating performance, all 26 microwaves delivered what we would describe as "just fine" reheated food, with some hot spots and some tepid areas. This mature product category, existing for over 75 years, has largely solved the problem of microwave heating, and the inherent physics limits further advancements. You can read here how even the inverter power control circuit fails to significantly affect performance.

This is liberating news for shoppers who are not one to become paralyzed by options. Since all microwaves perform similarly in heating food, you can choose your next microwave based on other factors that suit your needs:

- Dimensions: What fits in your kitchen and accommodates the dishes you use.

- Power: How quickly it heats your food.

- Design: Aesthetics like color, door mechanism, and installation type.

- UI and Extra Features: Controls (buttons or dials), interior lighting, sensors, and cooking presets.

Indeed, we test for these aspects in every microwave review! We invite you to explore our table tool to compare these features and find the best microwave for your needs. The microwaves we tested range from $90 for the Insignia NS-MW09SS8 to $399 for the Breville the Smooth Wave and up to $1,200 for the commercial Panasonic NE-12523. Despite this wide price range, all the models deliver the same heating performance, allowing you to focus on your budget and preferred features when making a choice.

Why almost everyone who rates microwaves uses a marshmallow test (and we tried to, too)

Most of our colleagues who rate microwave ovens include some variation of a heating evenness test based on the browning of marshmallows placed throughout the turntable. Using the cooked marshmallows as a "heatmap" is a seemingly great test; it's inexpensive, repeatable, and visual.

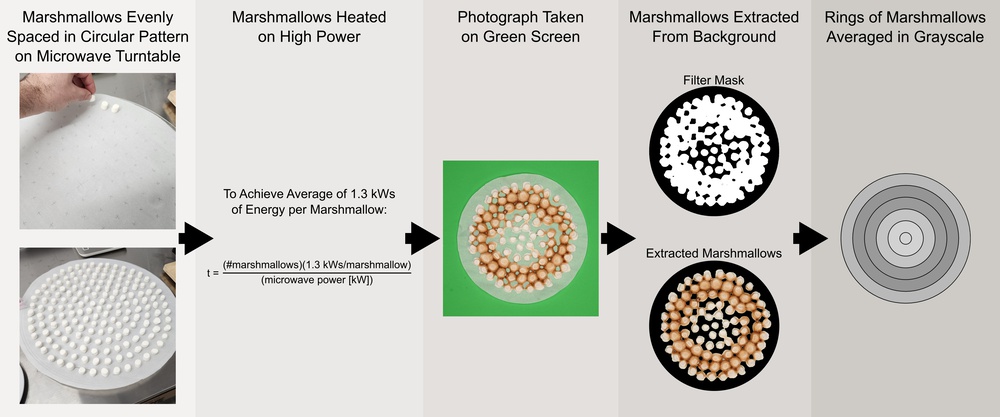

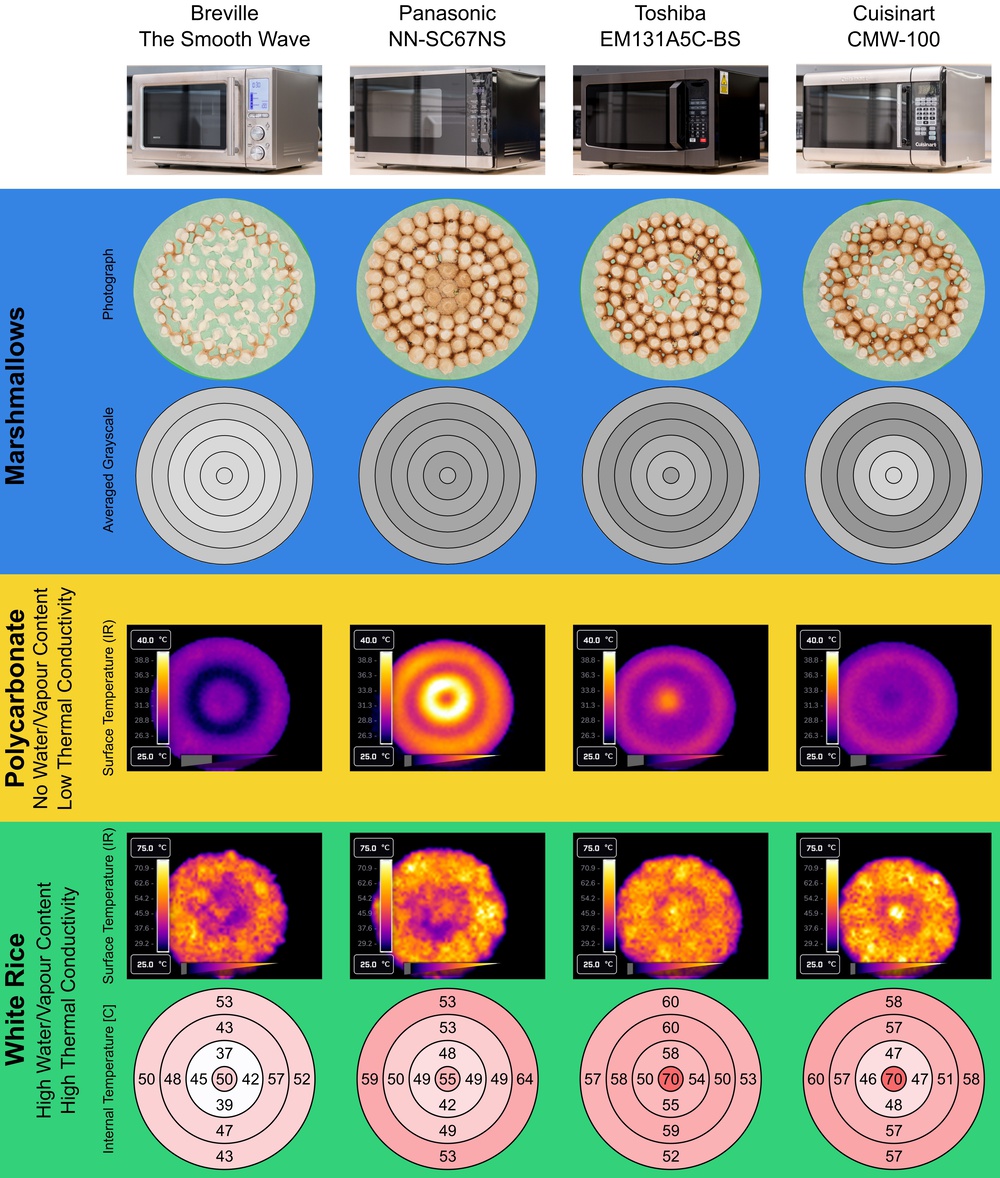

Indeed, as shown in the following figure, we tried to improve this ubiquitous test for use in our test bench by placing the marshmallows in an equally spaced circular pattern across the turntables. We next opted to normalize the amount of microwave energy (expressed in kilowatt-seconds, kWs) to the number of marshmallows present during the tests. Appliances with larger diameter turntables have more marshmallows placed on them and consequently have a relatively longer cooking time. With similar logic, appliances with higher output power (energy per unit time) have a shorter cooking time. Finally, we incorporated well-controlled photography of the resulting marshmallow heatmaps followed by image analysis techniques to automatically extract the area of marshmallow that's underheated and the range in browning that each microwave produces.

We attempted to improve the ubiquitous microwave marshmallow test by equally spacing the marshmallows, normalizing cooking time to the number of marshmallows and microwave power, and using image analysis techniques.

While we've proven that the marshmallow test we've devised gives repeatable results, and at first glance, the results vary from appliance to appliance, we began to wonder how well we can extrapolate these results to real foods that one would actually care to heat in a microwave.

Vertical placement in the cooking chamber and the number of marshmallows affect the results

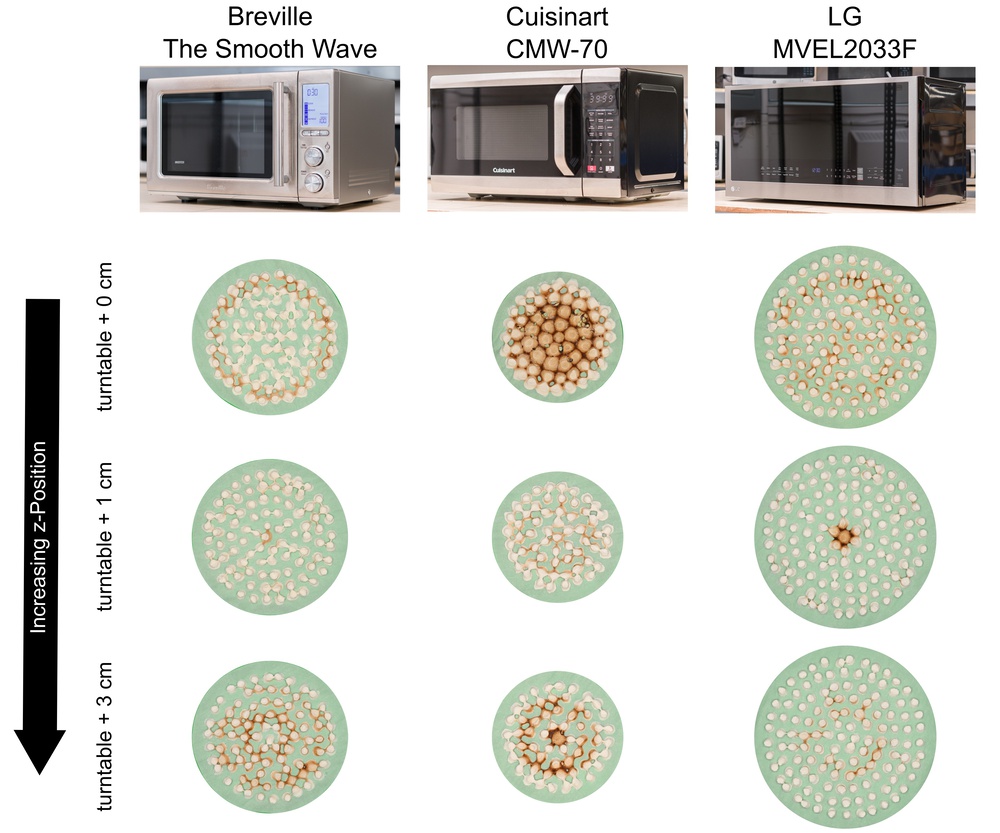

We first questioned how the thickness of the food (and the dish it's sitting on) affects the evenness in heating. We attempted to elucidate this connection by running the marshmallow test in three microwaves with increasing vertical positioning above the turntables. As you can see in the following figure, adding spacers such that the plate of marshmallows is 1 cm, then 3 cm above the turntable dramatically changes the test results. There are horizontal planes within the cooking chamber where the marshmallows come out darker/lighter and more/less evenly heated.

Vertical positioning within the cooking chamber greatly affects the marshmallow test results, suggesting that food thickness is a very important parameter.

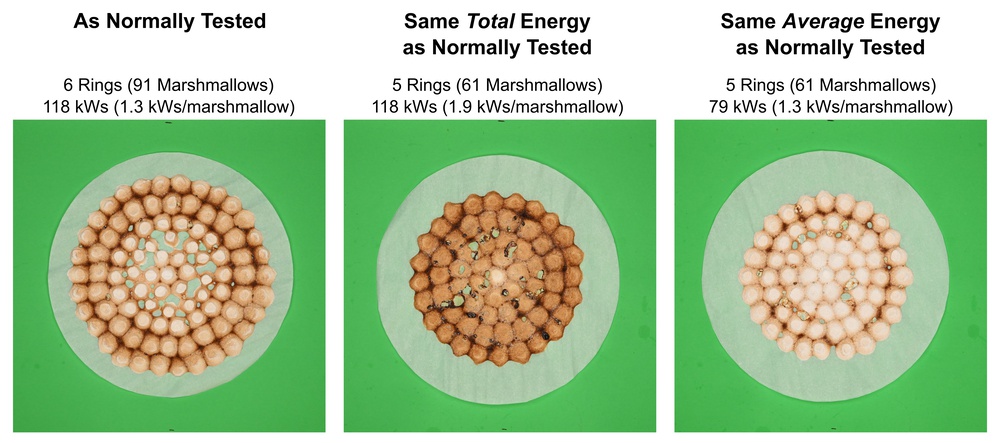

We next wondered what effect the number of marshmallows would have on the test results. In the normal test, the turntable diameter determines the number of marshmallows placed. As shown in the following figure, we repeated the marshmallow test in the Panasonic NN-SN67HS with the outermost ring of marshmallows removed. Microwaving five instead of six rings of marshmallows has led to increased evenness in browning; the presence of that outermost ring indeed affects how the inner marshmallows are heated. The figure also shows how we attempted to heat the smaller number of marshmallows with (i) the same total energy as the normal test (middle photograph) and then (ii) with the same average energy per marshmallow as the normal test (rightmost photograph). As expected, the smaller amount of heated food gets much darker with the same microwave energy/cooking time. However, the smaller amount of material can't be directly compensated for by considering normalized microwave energy; the rightmost photograph shows how we got very pale marshmallows by keeping the average energy constant at 1.3 kWs/marshmallow.

The amount of food greatly affects the results of the heating evenness of microwaves. The Panasonic NN-SN67HS produced more evenly browned marshmallows with the outermost ring removed. The overall degree of browning is affected by the number of marshmallows and isn't directly linked to normalized energy.

In sum, these additional investigations suggest that the shape, placement, and amount of food directly affect how evenly a microwave will heat said food. Importantly, this means that one can't look at a marshmallow heatmap and deduce how well the microwave that produced it will perform with all other foods one might want to heat with the appliance!

The amount of water vapor within the cooking chamber affects heating evenness

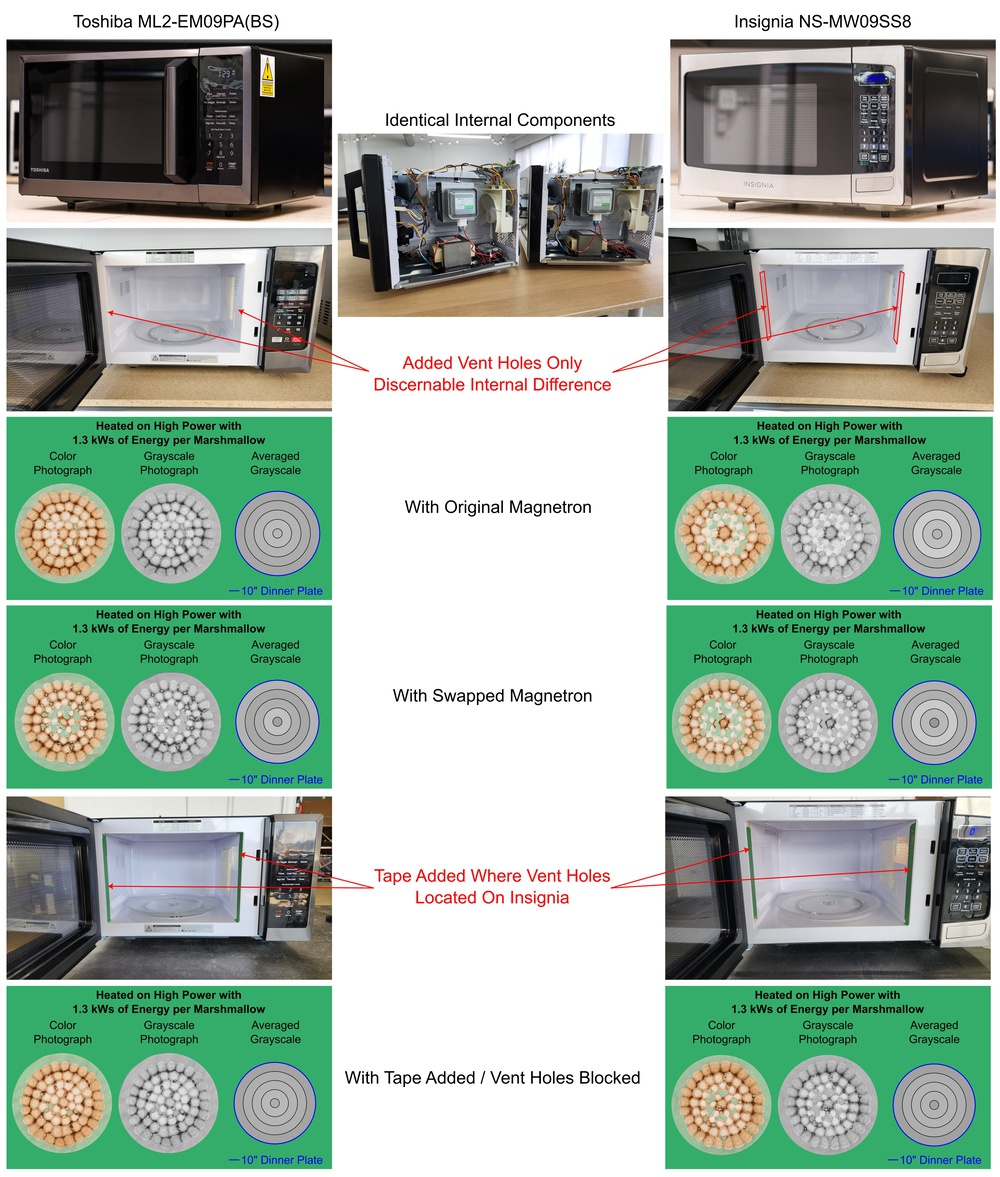

It's now common knowledge that most microwave ovens come from only a handful of factories in the world—the company Midea is responsible for the manufacture of microwaves for many brands. Two such "badge-engineered" models ended up in our test bench, the Toshiba ML2-EM09PA(BS) and the Insignia NS-MW09SS8, which have identical internal components (identical part numbers). As shown in the following figure, apart from their exteriors, the only discernable difference between these appliances is the added vent holes just behind the door of the Insignia. Interestingly, the Toshiba produced what could be described as one of the most even marshmallow heatmaps of the cohort. In contrast, the Insignia produced what could be described as one of the most uneven!

These two microwaves, which give differing marshmallow test results, have identical internal components except for added vent holes. Swapping magnetrons allowed us to conclude that the difference doesn't stem from manufacturing tolerances in this component. Blocking the added vent holes yields very comparable results, suggesting that the amount of water vapor within the cooking chamber affects heating evenness.

We first hypothesized that loose manufacturing tolerances in the magnetrons (the vacuum tube that produces the microwaves) are to blame for the differing performance in this test. However, as the previous figure shows, swapping the magnetrons with identical part numbers did not change the resulting marshmallow heatmaps. NOTE: don't try this at home; microwaves have high-voltage capacitors, which can be extremely dangerous! Leave the cover on your microwave unless you're a skilled technician.

So, it appeared that the marshmallow test performance difference was due to the addition of those vent holes in the Insignia model. Indeed, when we cover those holes with tape (and place tape in the same area of the Toshiba for good measure) and run the marshmallow tests again, the resulting heatmaps are remarkably similar. Those vent holes were evidently added to the design to prevent the window from fogging up; blocking them with tape led to noticeably more moisture on the inside face of the window. This means that more water vapor remains in the cooking chamber when those vents are blocked, and added humidity affects the heating of the marshmallows. As the moisture within the cooking chamber comes from the food being heated, and that food will, in all likelihood, have a different moisture content than that of marshmallows, we yet again conclude that one can't extrapolate from a marshmallow heatmap to the reheating performance of a microwave for other shallow dishes of food.

The thermal properties of the food dictate heating evenness

As the amount of water vapor within the cooking chamber plays a large role in heating evenness, we next experimented with an analog material that contains no water and will produce no water vapor when heated in the microwave—1/8"-thick Lexan polycarbonate. The following figure presents infrared thermal images of Lexan, cut to the diameter of the turntables, and heated on high power with 36 kWs of energy. As Lexan has very low thermal conductivity and produces no water vapor, it's heated with a distinct ring pattern in all four microwaves we tested. That is, the temperature gradient within the Lexan directly matches the locations of maximum energy peaks and troughs of the standing microwave (with the circular symmetry coming from the turntable rotating relative to the standing wave). That heat essentially doesn't conduct to the other areas of the Lexan before the IR image is taken. It's very interesting to see how the location and intensity of the temperature rings in the Lexan don't match the rings given by the marshmallow test.

The thermal properties of the food dictate how evenly it will be heated in a microwave. Polycarbonate is an extreme analog material that produces no water vapour and has very low thermal conductivity; it will always be heated in a circular pattern. Chilled white rice has a high water content and relatively high thermal conductivity, and thus, it gets heated rather evenly by the appliances. The heating pattern of the white rice doesn't at all match the results of the marshmallow test.

We next tested with real food, white rice, which is on the other end of the material thermal property spectrum. While still solid, the white rice has a high water content and a large void volume (where we hypothesize water vapor can easily travel). We spread 6 cups of cooked and then refrigerated white rice over the turntables of four microwaves and heated it on high power with an average energy of 0.33 kWs per cm2 of turntable. The results of these experiments with rice are presented beside the results of the marshmallow and Lexan heating experiments in the previous figure. The IR images show that the surface of the rice was heated up rather evenly in all four microwaves, and just below temperature probe measurements show that the rice was also heated up rather evenly in its bulk.

There are two important conclusions to draw from the white rice reheating experiments. The first is that the heating evenness of this food doesn't at all match the heating evenness shown by the marshmallow test or the Lexan test. For example, the microwave that produced the most unevenly-coloured marshmallows—the Cuisinart CMW-100—yielded evenly-heated rice. The second conclusion is that the numerical differences in the temperature measurements are rather trivial when put in context by a taste test. All the microwaves produced rice with some hot and some tepid areas, and we agreed that the sensation of eating this rice was the same across the board.

In sum, the marshmallow test could not predict how real food (rice) would be heated and that real food was heated equivalently by all the microwaves.

The Deep-Dish Heating Evenness Performance of a Microwave Is Also Controlled by the Food

So, the marshmallow heatmaps that most of our colleagues use to test a microwave's shallow dish heating performance don't reflect how a microwave will perform with real food. Our testing reveals that the foods' characteristics determine the evenness of heating and that all microwaves produce the same results with shallow dishes. The next logical question is, do all microwaves perform the same when heating deep dishes of food?

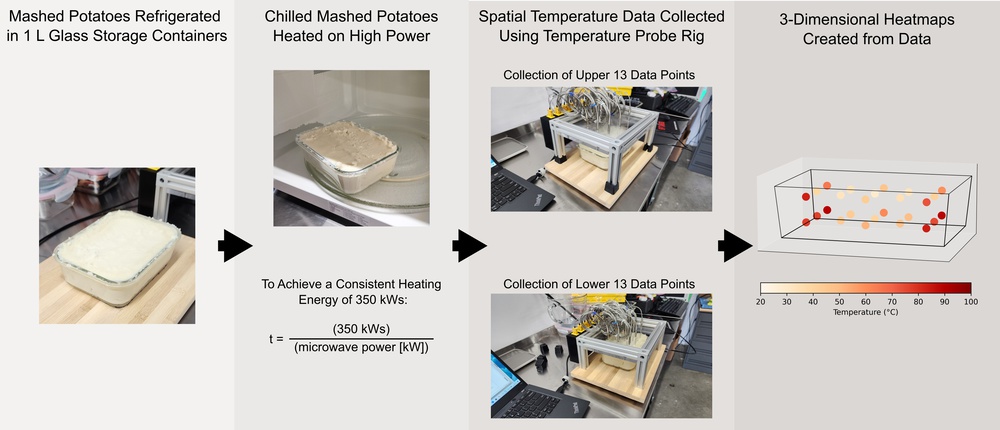

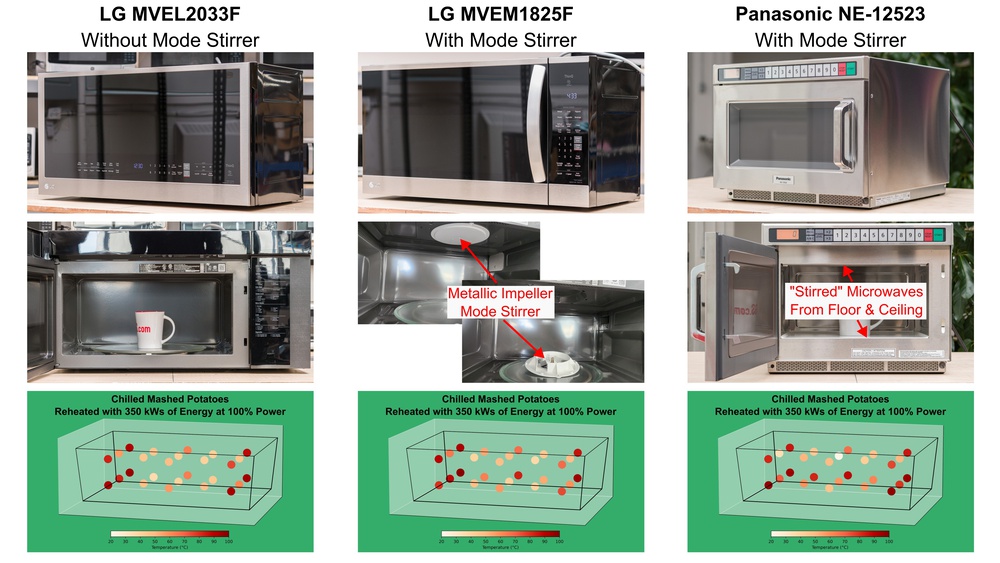

To elucidate the appliances' performance with heating deep dishes of food, we devised a test as outlined in the following figure. The test consists of a typical 1 L rectangular glass food storage container of refrigerated mashed potatoes which are heated with 350 kWs of microwave energy. The spatial temperature gradient of the resulting food is then collected using a rig of 13 temperature probes. And finally, 3-dimensional heatmaps are built from this collected data.

All the mashed potato temperature distributions turned out statistically equivalent

The following bar graph presents the mean temperature measured in the containers of mashed potatoes reheated with each of the microwaves we tested. The error bars in this graph represent standard deviations in each of the datasets (of 26 temperature probe measurements). When viewed as a cohort, we see that all the appliances produced equally mediocre mashed potatoes. First, the mean measured mashed potato temperatures are all statistically equivalent. Second, every microwave produced containers of mashed potatoes with both overly hot and overly cool areas, as shown in the large standard deviations in the datasets.

The mean of the mashed potato temperatures measured after heating with 100% power in each of the tested microwaves. Error bars represent one standard deviation from the mean. All microwaves produced statistically equivalent mashed potatoes.

It's especially interesting that none of the over-the-range microwave models with "mode stirrers" in the ceilings of their cooking chambers, like the LG MVEM1825F, produces more evenly heated mashed potatoes. As shown in the following figure, a mode stirrer is a metal impeller from which the microwaves are reflected. The continual spinning of the impeller means that the microwaves are reflected at changing angles, and the standing wave is less stationary (with the high-energy areas moving around the cooking chamber). The commercial appliance we tested—the Panasonic NE-12523—splits its power such that microwaves are output from the floor and ceiling of its cooking chamber and includes two such mode-stirring devices, yet it fails to produce mashed potatoes with increased evenness.

Mode stirrers that reflect the microwaves and move the resulting standing wave around the cooking chamber don't produce more evenly heated mashed potatoes. Even the commercial Panasonic NE-12523 we tested, with microwave output from above and below, failed to prepare evenly heated food.

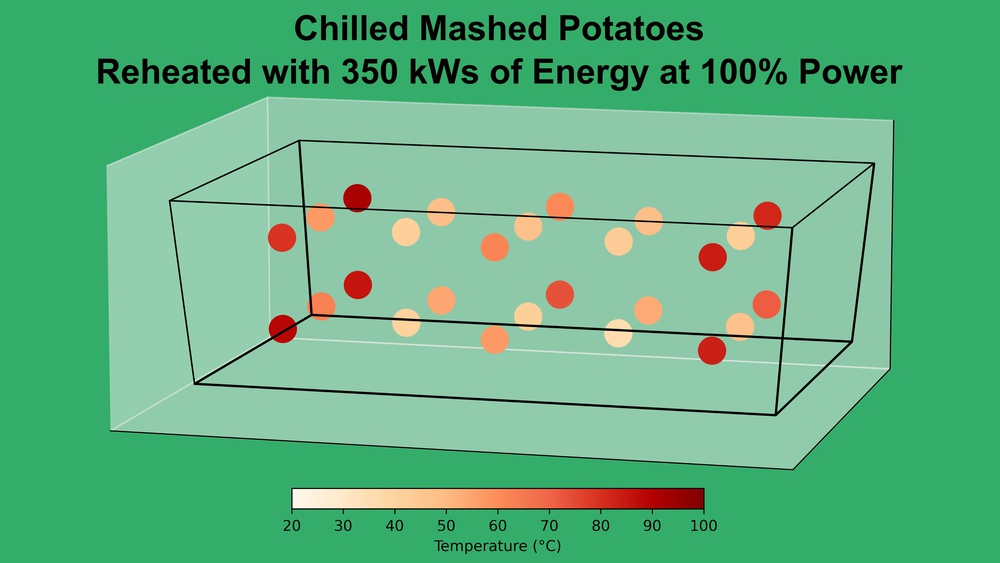

One final observation we made with the deep-dish reheating tests was that the location of hot and cold areas within the mashed potatoes was remarkably similar for all the microwaves in the batch. A typical 3-dimensional mashed potato heatmap (taken from the GE JES1072SHSS) is shown in the following image. These results demonstrate how physics and mashed potato heat transfer properties ultimately dictate the resulting temperature gradient. The hottest recorded temperatures are found in the corners of the glass storage containers. The reason is four-fold:

- Glass is virtually transparent to microwaves. Thus, the energy from the appliance passes through the food storage container and penetrates the surface of the mashed potatoes.

- Glass is an okay insulator of thermal energy, limiting heat transfer away from the food to the surrounding air in the microwave oven.

- Microwave energy only penetrates about 1 to 3 cm into the food that's being heated in the appliance. In fact, the 2.45 GHz frequency at which microwaves operate is chosen to balance penetration and absorption. Therefore, only the water molecules (and other polar components) in the outermost few centimeters of mashed potatoes absorb the microwave energy, vibrate, and are consequently heated up.

- Mashed potatoes are also poor at transferring heat; they have a thermal conductivity on the order of 0.5 W/m•K and are a semi-solid (actually a "colloidal suspension") such that there's no natural convective heat transfer occurring. Therefore, the thermal energy tends to remain at the surface of the mashed potatoes, leaving the center cold.

Worried that you still might not believe us, we microwaved soup

The diligent reader will have noticed that in the previous section, none of the characteristics that explain the universally poor mashed potato reheating results are related to the microwave oven appliances themselves. That is because all the appliances we purchased (and indeed any microwave oven that you'll come across) have the same basic attributes: a magnetron that outputs microwaves with a frequency of 2.45 GHz (within the radio bands that government agencies set aside for industrial, scientific, and medical uses), a cooking chamber which reflects and contains the waves (leading to the formation of a standing wave), and some mechanism to move food relative to this standing wave (almost always a turntable, unless you buy a commercial model with a mode stirrer). Therefore, your food is ultimately undergoing the same physics-controlled experience, whether inside a Panasonic, Insignia, or Toshiba microwave oven. In any case, you'll have to stir your food upon removing it from the appliance to get the best results.

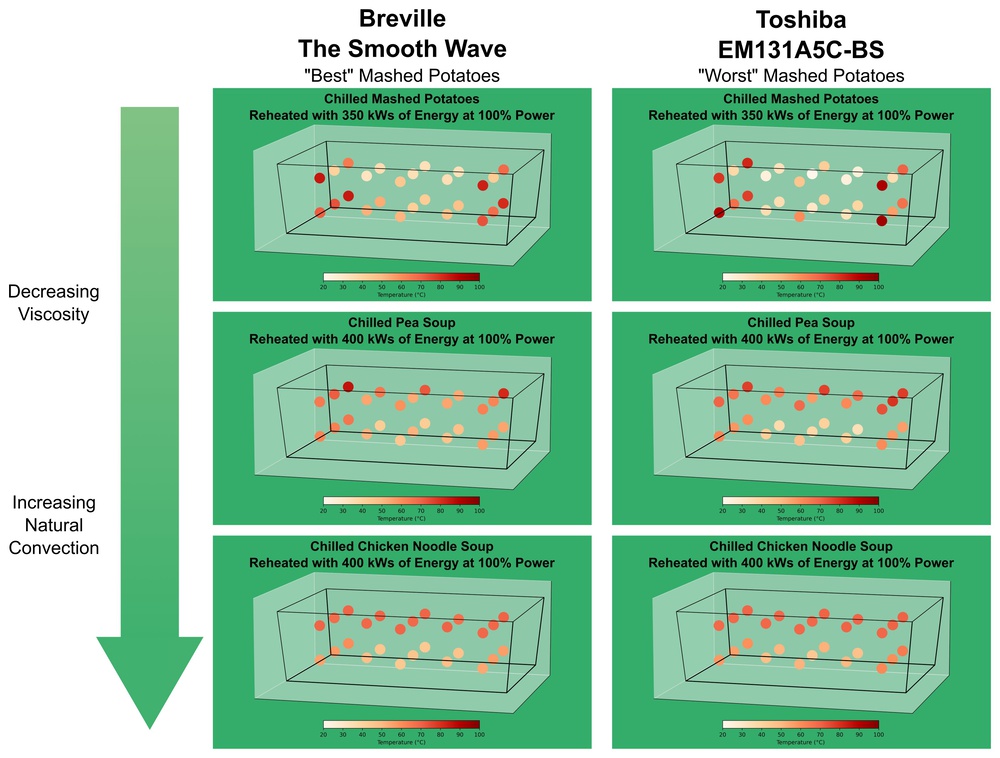

We can drive the point home that all microwave ovens have the same heating performance, and indeed, the food you microwave will determine heating evenness with the results of one final test. The following figure presents the 3-dimensional mashed potato heatmaps collected from the Breville the Smooth Wave (which one could erroneously conclude to be the "best" results) and the Toshiba EM131A5C-BS (which one could erroneously conclude to be the "worst" results). When chilled pea soup and chilled chicken noodle soup are heated in the same glass food storage containers, the results from both appliances become indistinguishable. While the thermal conductivity of chicken broth (mostly water with some fat and dissolved solids) is not that different from mashed potatoes at approximately 0.6 W/m•K, the viscosity is much lower. As viscosity decreases, natural convection resulting from changes in density upon heating can occur within the food. Essentially, the food partially mixes itself. In sum, as with all our other tests, the results depend very heavily on the food being heated. And any perceived performance differences are simply noise in the data.

What About Popcorn? What About Meat Defrosting?

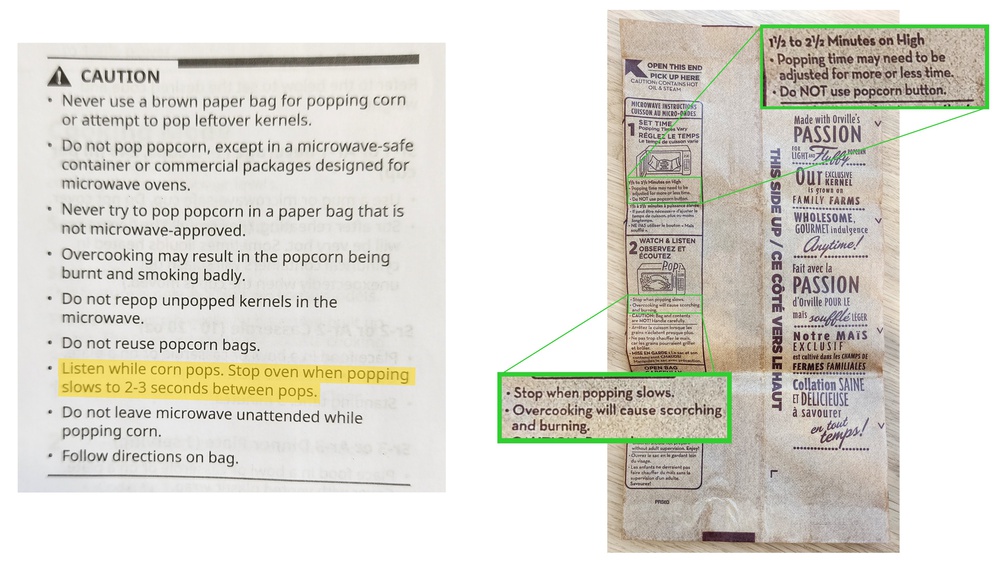

For many people, the microwave oven is simply a popcorn machine. And it actually is really great at this task! However, you'll notice that our microwave oven reviews don't include a test for popcorn. Again, this is deliberate, and we came to this decision for two reasons. (i) As we hope we've convinced you, all microwaves have essentially the same heating performance, which applies to popcorn preparation! And (ii) there are natural variations in the properties of popcorn from batch to batch (e.g., moisture content of the kernels), which preclude the design of a meaningful performance test. As shown in the following figure, if you check the back of a package of microwave popcorn or the user manuals of many of the microwaves we tested, you'll notice that you are instructed to wait beside the microwave and manually end the heating cycle once the interval between popping slows to between 2 and 3 seconds. Furthermore, even most microwaves that include a cooking sensor, like the Panasonic NN-SN67HS, do not make use of that sensor when you hit the dedicated "popcorn" button (that popcorn button is usually just a timer!). In sum, you can feel comfortable knowing that any microwave you buy will pop popcorn just fine! But it may take some trials to find the perfect time for your machine.

These are photographs of popcorn instructions from the LG LMC0975ST user manual (left) and a bag of Orville Redenbacher microwave popcorn (right). Both instruct a user to manually stop the microwave when popping slows.

Another frequent use of the microwave is the quick defrosting of meat. Here again, we've opted not to include such a test in the review of each appliance. However, we've performed many defrosting tests (with 1-lb portions of frozen medium ground chuck) throughout the development of this test bench. We detail the defrosting performance of inverter versus non-inverter models of microwaves in another published R&D article. While each model of microwave has its own specific routine of pulsing the power to effectively defrost meat, we've found that the physics of microwave-water interactions and heat transfer into the bulk frozen meat are what controls this process. All microwaves (from the least expensive Insignia NS-MW09SS8 to the most expensive Breville the Smooth Wave) can defrost meat. However, none of them offer a completely hands-off experience. To completely defrost meat without cooking any edges, at the halfway point in the process, you must remove any defrosted portions and flip what remains frozen before proceeding. On top of that, you must let the meat stand on the countertop after the microwave has finished to allow the remaining frozen center to finally thaw. Reworded, you can also feel comfortable that any microwave you choose can defrost meat, but don't expect it to do all the work for you!

Conclusions

Our extensive testing of 26 different microwaves revealed a surprising result: there are no significant performance differences in terms of heating evenness among the models tested. Despite our rigorous methodologies, including improvements on the ubiquitous marshmallow heatmap test and thermocouple arrays to capture 3-dimensional temperature data in deep dishes of food, all microwaves produced similarly heated food with minor variations attributed to noise in the data rather than the appliances themselves.

This finding underscores that the characteristics of the food, like its water content, shape, and thermal properties, play a far more crucial role in heating evenness than the microwave oven itself. For this reason, we've opted to score only the "power" box of the reviews. The output power of the appliance directly determines how fast you can heat food, and most recipes are written for 1000 W microwaves. Ultimately, consumers can confidently select a microwave based on other factors, like dimensions, power, design, and user interface features, knowing that any model will adequately heat food.