Buying a refrigerator today can be a daunting task. Our initial test bench already covers essential performance and design aspects across basic, top-freezer models to higher-end, French door models. However, through our research and development of the product category, it became clear that there's one aspect we haven't captured: reliability. Amongst seas of negative reviews, class-action lawsuits, and over a dozen manufacturers churning out new models every three to four years, it has become harder than ever to identify a fridge that's going to last.

Ideally, a fridge will reliably do its job for many years without breaking down. Unfortunately, this doesn't seem to be the case in modern years. As with most household appliances, refrigerators have become increasingly complex, feature-loaded products with ice makers, precisely controlled temperature/humidity zones, smart app connectivity, and in some cases, full-blown Android tablets implemented in their doors. While the performance, efficiency, and usefulness of refrigerators have greatly improved, ultimately, the complexity added by new components and features can have a negative impact on their reliability.

Reliability, as a concept, is the ability of a product to perform its intended function over time without failure. Later in this article, we'll go further in-depth on the difficulty of gauging refrigerator reliability, including our own attempt at accelerated life testing (ALT), but in short, reliability data isn't publicly accessible, and accelerating the lifecycle of something that's already designed to run 24/7 for years on end is less effective. Furthermore, given how often manufacturers release new models, the reliability of appliances tends to be cyclical, meaning that the most reliable brand this year might not be the case in a few years' time.

Bearing all of this in mind, we shifted our focus to after-purchase serviceability support. It's often safer to assume when a refrigerator will break down, not if. And when that happens, what really matters is how quickly and easily you can get it running again. To paint a clearer picture of what that means for consumers, we analyzed the authorized service coverage and parts availability across each brand that we've currently tested.

To better understand the appliance repair industry as a whole, we sent a pair of RTINGS employees to Fred's Appliance Academy in Ohio to complete training as certified appliance repair technicians. Fred's Academy has been an invaluable resource in understanding the greater picture of appliance reliability, and we've used their knowledge and insights directly in this article.

If you're currently or soon to be in the market for a new refrigerator, the best way to protect your investment is to shop for service before you need it.

The Importance of Service Coverage

Appliance manufacturers release new refrigerator models every few years, often with redesigned components from different suppliers and factories. In these early stages of the product's lifecycle, even the manufacturer doesn't fully know how reliable the product will be. As a consumer, your protection comes from the warranty, which covers parts and repair costs during its term. But a warranty is only as useful as the service network behind it; if you can't find someone authorized to perform the repair, the warranty offers little real value.

Factory Authorized Service Matters

When a refrigerator experiences a failure within its warranty period, manufacturers will always try to connect with a service provider in your location who is authorized for their brand of products. This matters because:

- You can book repairs directly through the manufacturer's service page.

- The technician has brand-specific training, OEM parts, and service manuals, leading to faster diagnoses and repairs.

- The repair won't void the manufacturer's warranty.

- Billing is handled directly by the manufacturer.

If there are no authorized service providers in your area, the process can become much more difficult:

- The manufacturer may try to find a service provider outside of their regular service network, which can lead to longer downtime for your refrigerator.

- You may need to hire a technician yourself, pay upfront, and then request reimbursement, a process that can cost several hundred dollars out of pocket.

- You may be forced to have a non-authorized technician repair your appliance, pay out of pocket, and risk voiding the warranty entirely.

- In extreme cases, you may have to transport the refrigerator yourself to an authorized service center for repairs.

- It's also worth noting that some technicians may refuse to work on certain brands entirely.

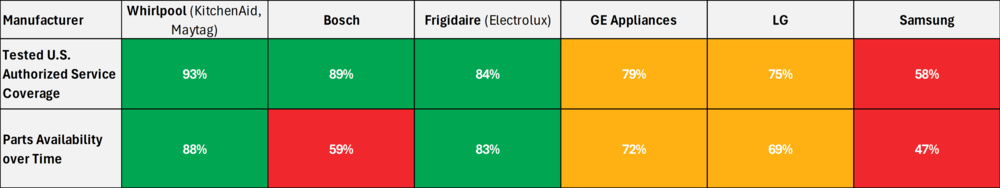

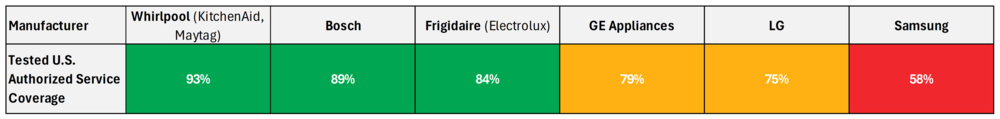

Comparison of U.S. Service Coverage Across Brands

To test service coverage, we built a map of the contiguous United States with 228 cities and towns, from major population centers like Los Angeles to rural locations such as Grangeville, Idaho. The locations were chosen to include major hubs, at least one urban and one rural site in every state, and to ensure complete geographic coverage across the country. For each location, we used each brand's online service tool to enter the model numbers of our tested refrigerators, warranty details, and a local ZIP code. If the tool matched our search with an authorized service provider within 50 miles, the brand scored a 1 for that location. If the matched service provider was farther than 50 miles, or if none were listed, the location scored a 0.

This process was repeated for every brand in our initial batch of tested refrigerators:

- Whirlpool (including KitchenAid and Maytag)

- GE Appliances

- Bosch

- Frigidaire (Electrolux)

- LG

- Samsung

Based on the coverage results, we generated an HTML map, shading each state from clear (0%) to dark green (100%), representing the percentage of locations with authorized service coverage. In the interactive map below, you can toggle each brand in the legend (in the top right corner) to view its coverage results. Clicking on a state opens a tooltip with the results for each location:

As of the date of publishing, the results from the test are discussed below:

- Whirlpool: Whirlpool offers the most robust service network, with their authorized service provider matching our searches with 93% (212/228) of tested locations. The few misses were almost entirely rural (e.g., Grangeville, ID) with only one notable hub (Fort Wayne, IN) lacking an authorized provider.

- Bosch: With coverage in 89% (202/228) of tested locations, Bosch maintains the second strongest service network. While coverage thins slightly in less-populated states (WY and SD), they provide excellent access in both major metros and rural regions in most states.

- Frigidaire (Electrolux): Frigidaire offers the third-best service network, with coverage in 84% (191/228) of tested locations. As with Whirlpool and Bosch, most gaps appear in smaller, rural locations. However, Frigidaire has at least one authorized service provider in every state, ensuring baseline coverage nationwide.

- GE Appliances: GE Appliances covers 79% (179/228) of the tested locations. GE's service network shows fairly comprehensive coverage but leaves some noticeable gaps. Misses occur not only in rural towns, but also mid-sized cities like Columbus, GA, and Grand Junction, CO. In 2024, GE announced their revamped service arm, Bodewell, who are currently increasing their nationwide coverage.

- LG: With coverage in 75% (170/228) of tested locations, LG's authorized service network is decent. They cover most major metros but have significant coverage gaps across the Midwest and Mountain states.

- Samsung: With coverage in only 58% (133/228) of tested locations, Samsung has by far the weakest service network among the major brands. While you'll be covered if you live in a large metro area, authorized service drops sharply across the Midwest and interior states. Despite holding the largest U.S. appliance market share in 2023, Samsung's service network lags behind sales, reinforcing customer complaints of long wait times and difficulty accessing warranty repairs.

In summary, Whirlpool stood out with near-universal coverage, making it a safe bet for authorized service regardless of location. Bosch and Frigidaire also show comprehensive service coverage, while GE and LG showed more gaps outside of major metros. Samsung trailed with the weakest network. That said, these scores reflect national averages. What ultimately matters is whether there's authorized coverage in your specific area. Even a brand with a weaker overall coverage can still serve you well if you fall within their network. If you live in a major metro, you will likely be covered regardless of the brand you choose. But if you're considering a brand with lower service coverage, the interactive map can be helpful at a glance to confirm their network is available in your area.

It's important to note that this study isn't perfect: a miss on our map doesn't mean you can't get service, only that finding factory-authorized support for in-warranty repairs will likely be more difficult. The map reflects a static study conducted in August 2025, and we plan to regularly update the results as service networks expand. If you're a factory-authorized provider in a location we missed, we'd love to hear from you so we can update the map.

Replacement Parts and Long-Term Support

Another key factor in a refrigerator's reliability is the availability of replacement parts when something fails. Just as car owners expect to replace components like brakes or tires over the vehicle's lifetime, it's not unreasonable to anticipate some level of upkeep (even though appliances are subject to far less stressful conditions than cars). Parts availability is crucial for repairing a fridge in a timely manner, and prices can vary widely between manufacturers and models. Overly expensive parts can be the deciding factor between repairing the fridge or replacing it altogether, especially if it's outside of the warranty period.

This aspect becomes even more important with higher-end and boutique refrigerators. If the upfront cost of a refrigerator is higher, ensuring a supplier keeps sufficient parts in stock, even later into the appliance's lifetime, can help protect your investment.

The Lifecycle of a Refrigerator

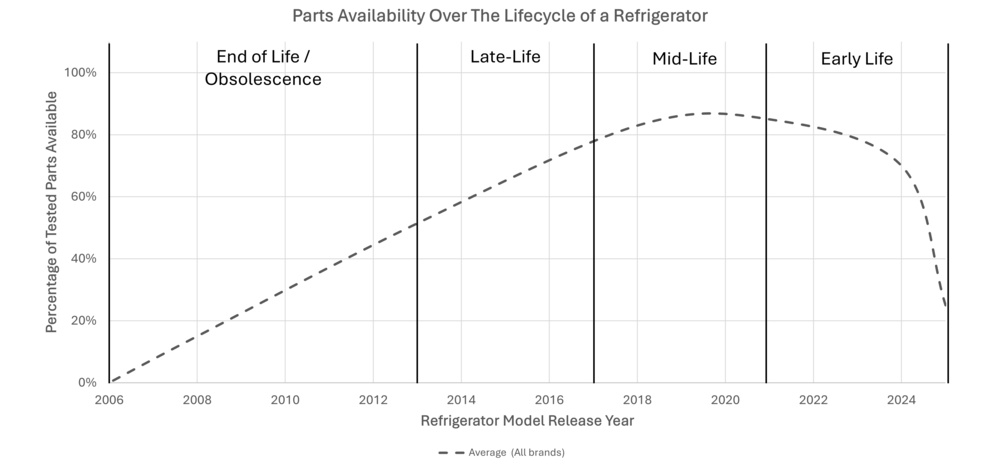

The support and availability of parts change over a refrigerator's lifecycle. For the purposes of this analysis, and given the average lifespan of 12 years for a modern refrigerator, we can subdivide its lifecycle into four stages:

- Early Life (0–3 years): Parts can be difficult to obtain for new refrigerators. Ongoing production of new models can lead to a lack of replacement parts. Or, if the appliance is suffering from a common design flaw, there can be part shortages while manufacturers deal with a high volume of warranty repairs for afflicted components.

- Mid-Life (3–8 years): Things tend to even out during the middle of a refrigerator's lifecycle, and by this point, many warranties are partially or fully expired. As new production of the model slows to a halt, replacement parts become more widely available. Any inherent design flaws of a particular model will be well understood, and production or redesigns for afflicted components will have had time to catch up. At this stage, repairs are usually more economical than replacing the appliance.

- Late-Life (8–12 years): In the later stages of a refrigerator's life, parts availability begins to diverge more between brands. Some manufacturers reuse components across multiple product generations, keeping them easier to source, while others provide updated numbers for discontinued parts. Model-specific replacements (PCBs and compressors) can spike in price at this age, often pushing owners toward replacing the appliance instead of repairing it. By this point, new models are also likely to offer improvements in efficiency and features.

- End of Life/Obsolescence (14+ years): Once a refrigerator reaches or exceeds its expected service life, replacement parts can become increasingly limited. At this point, repairs often become impractical or too costly, and replacing the appliance may be the most economical option.

The general evolution of refrigerator parts availability over its lifecycle is pictured below:

Assessing Parts Availability

To compare parts availability, we selected four popular French door models from each brand, spanning across the following lifecycle stages:

- 2023: Early Life

- 2018: Mid-Life

- 2013: Late-Life

- 2008: End of Life/Obsolescence

2024 to 2025 models were omitted from the study due to their low part availability across the board. We then selected three tiers of components that are common across all brands:

Common Failures: Parts that fail frequently under normal use and make up many service calls. They are usually less expensive and easier to replace:

- Ice maker

- Evaporator/condenser fan motor

- Thermistor (temperature sensor)

Wear Items: Components subject to mechanical or thermal fatigue over time. They aren't guaranteed failures, but degradation is expected after years of use:

- Defrost heater

- Door gasket

Critical Components: These parts normally lead to total failure of the refrigerator and can be expensive to purchase and install, driving the repair versus replace decision:

- Compressor

- Main control board

For each refrigerator model, the availability of each component was checked on the manufacturer's official parts site and four major U.S. suppliers:

Scoring was applied as follows:

- In stock: Component scored 1

- Back-ordered (21+ days) or No Longer Available (NLA): Component scored 0

The simple scoring structure allowed us to make an initial assessment of parts availability across brands and generations of models.

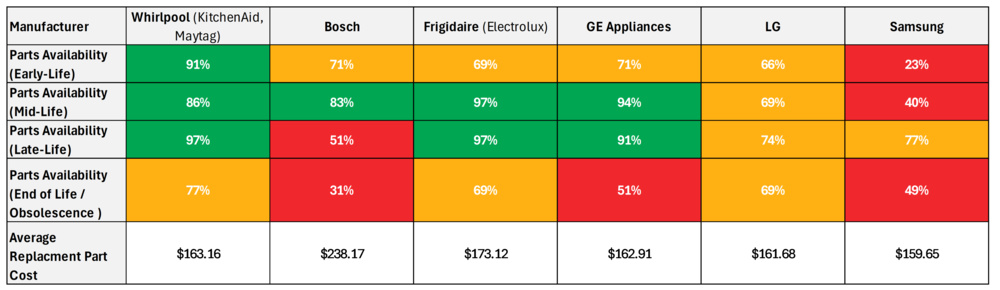

Replacement Part Availability across Brands and Model Years

Through the analysis, we were able to plot the availability of parts across model years for each brand and compare it to the average parts availability across all brands. If you're interested in the full dataset, the spreadsheet can be downloaded here.

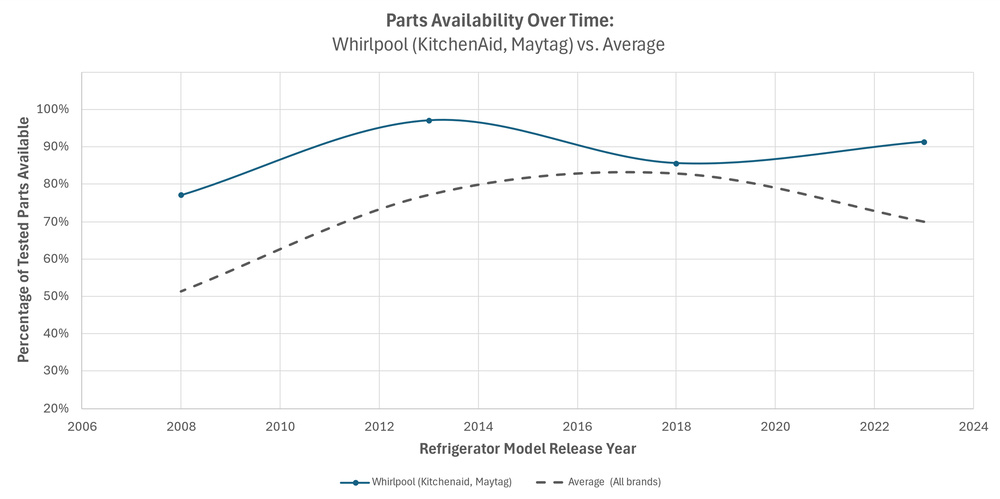

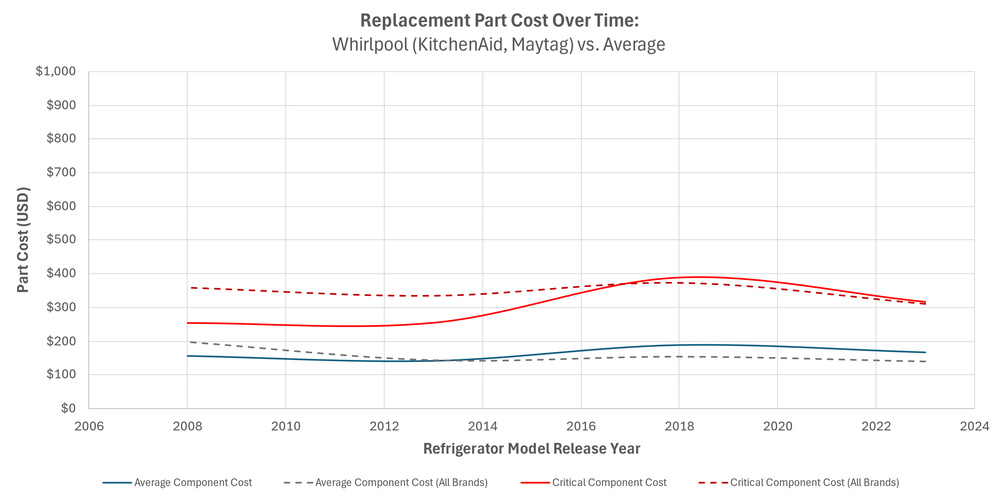

Whirlpool (including KitchenAid and Maytag):

Whirlpool outperforms the industry average across all years tested. Parts availability is strong even in newer models and maintains relatively high support over the entire lifecycle of their appliance. While there is a slight dip towards the EOL stage, 77% of tested parts remain available.

Additionally, the critical component cost remains consistent throughout the entire test period, meaning repair is a viable option even if the appliance is older. Whirlpool tends to reuse components across multiple generations and brands, keeping replacement availability high and cost-effective.

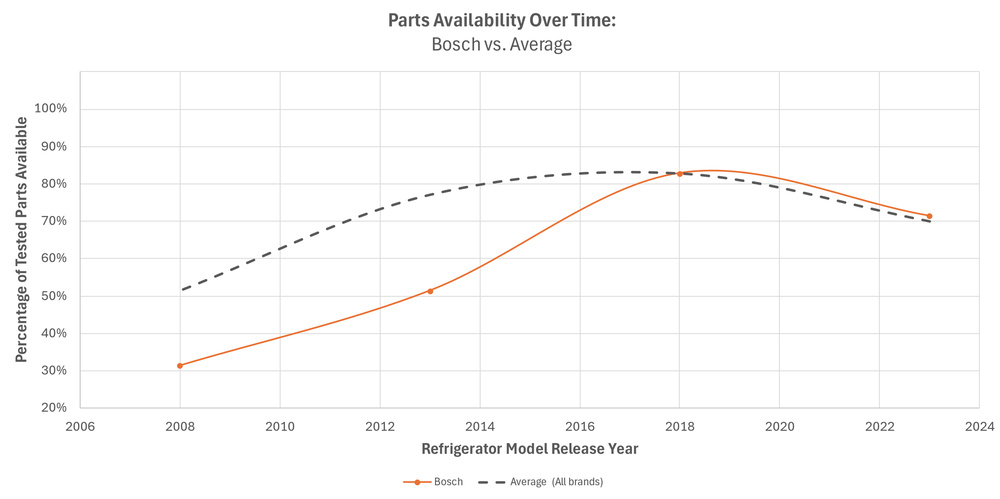

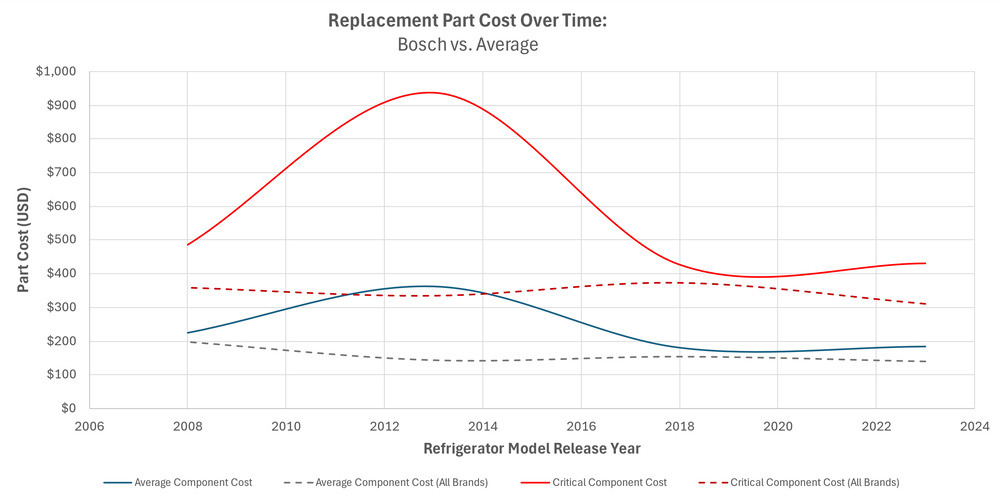

Bosch:

Bosch shows strong parts availability for early and mid-life models. However, they clearly taper off support much earlier than competitors. By the time models reach late-life to EOL, most suppliers no longer stock the necessary parts for repair.

Additionally, average part prices are higher across the board (not surprising given that Bosch refrigerators usually have a higher price tag), but their critical component cost is well above the industry average in later years, making replacement more feasible than repair for models older than 10 years.

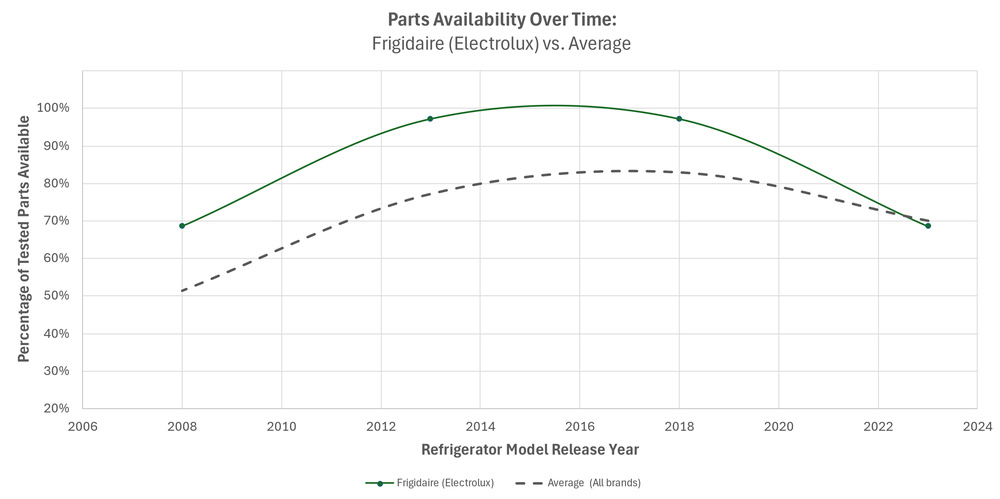

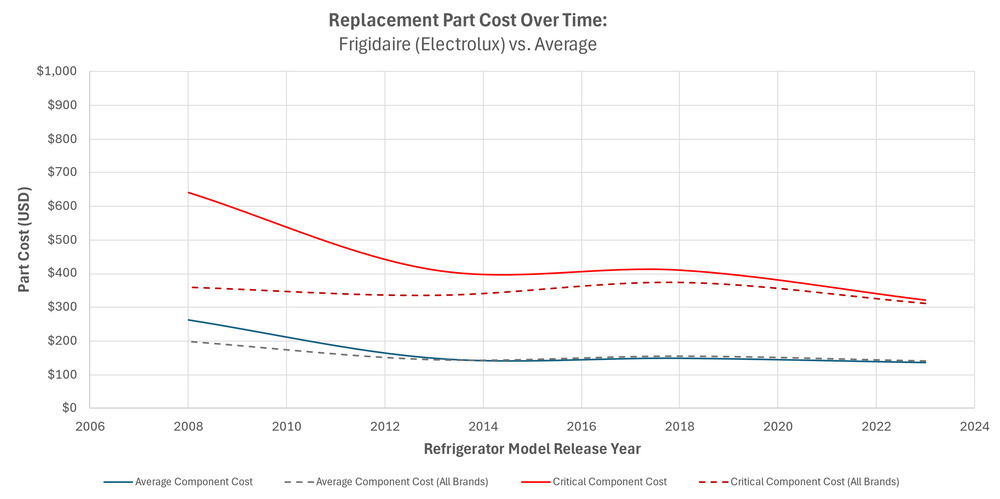

Frigidaire (Electrolux):

Frigidaire performs very well in terms of parts availability, with most suppliers stocking 100% of parts for mid-life to late-life models. The early life availability is on-par with the industry average, and even EOL models are well supported.

From a cost perspective, Frigidaire's average component prices track closely with the industry average, making common repairs affordable. However, compressor and PCB prices rise towards EOL models, limiting their long-term repairability in favor of total replacement.

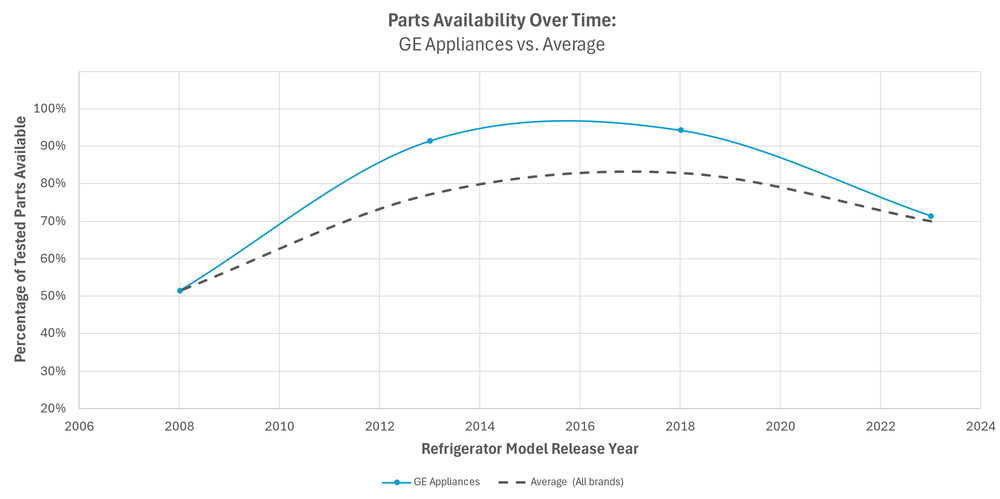

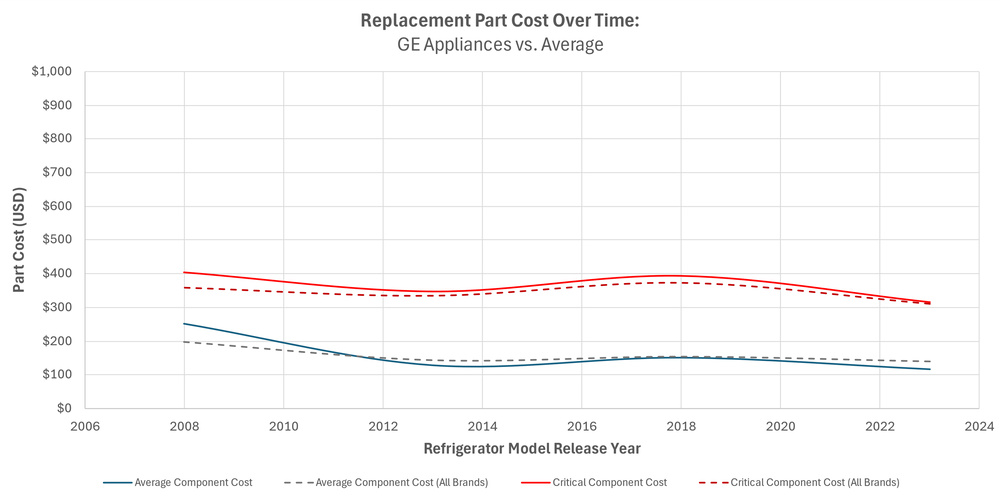

GE Appliances:

GE lands in a similar tier to Whirlpool and Frigidaire when it comes to parts support for early through late-life models. However, by the time units reach EOL stages, the support drops off, just barely above the industry average, with only around 50% of parts available amongst tested suppliers.

GE's component prices are steady and very close to the industry average, even into the EOL stage, making repairs economic regardless of age, although you may face greater difficulty finding parts as support tapers off.

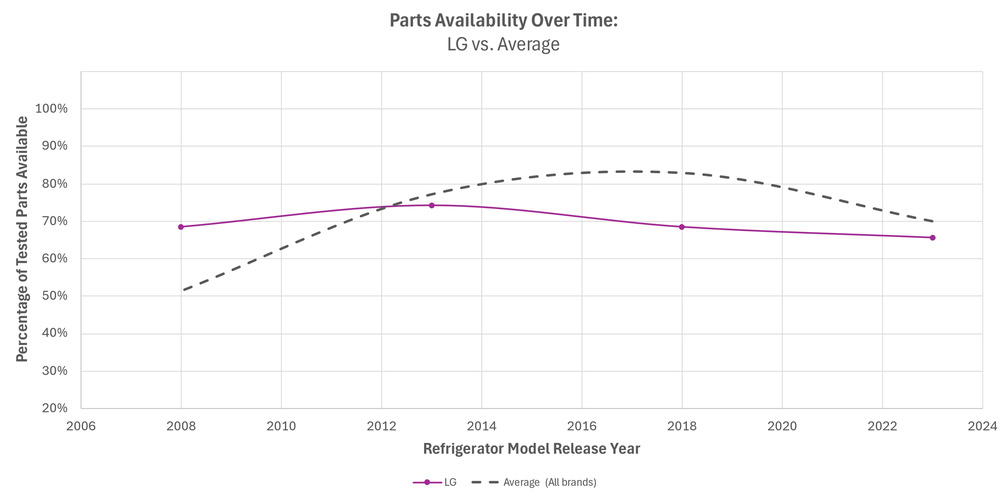

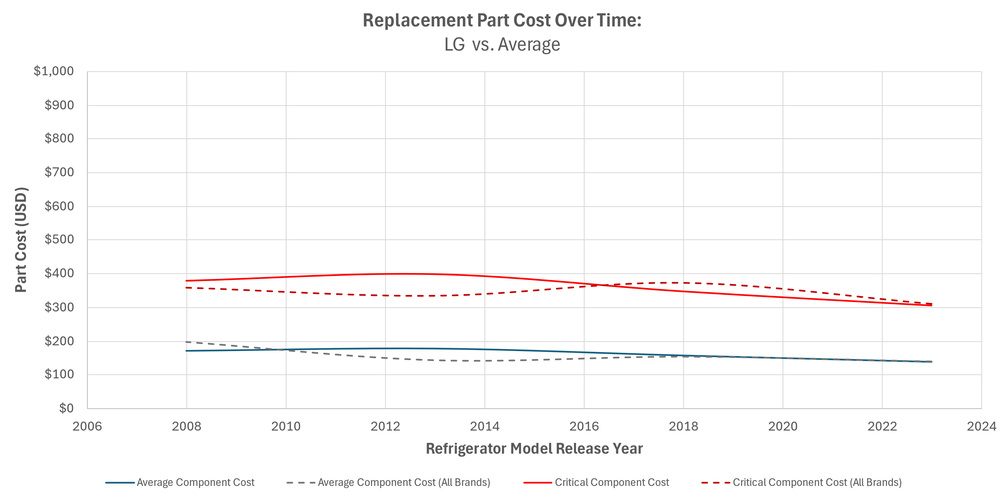

LG:

LG's parts availability is steady throughout the life of their appliances, but only exceeds the industry average for models released in 2008. At an average of about 70% across all tested years, replacement components will most likely be available, but not in abundance. This can lead to increased downtime while components are sourced.

Cost-wise, LG is consistent with the industry average. Like Whirlpool, LG reuses many components across multiple generations. Critical component cost doesn't meaningfully increase over the course of their lifespan, making repair feasible in the event of a compressor or PCB failure.

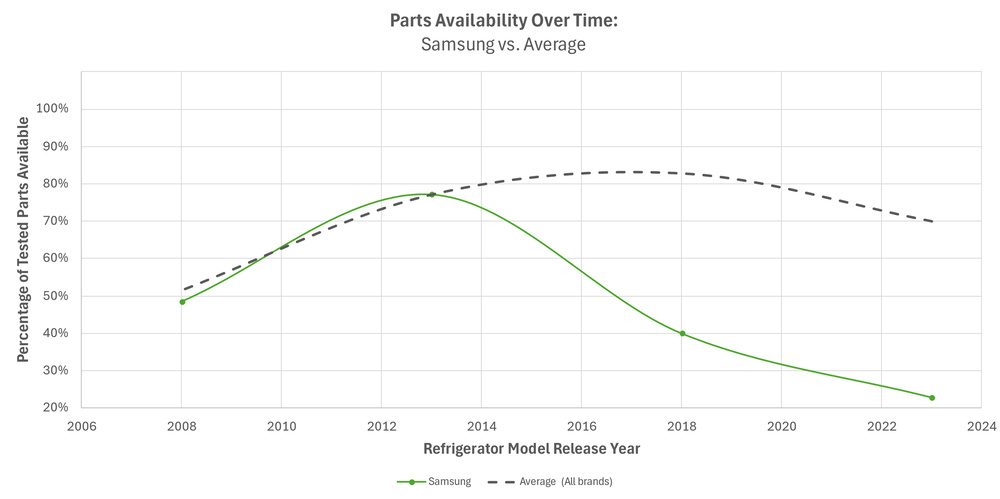

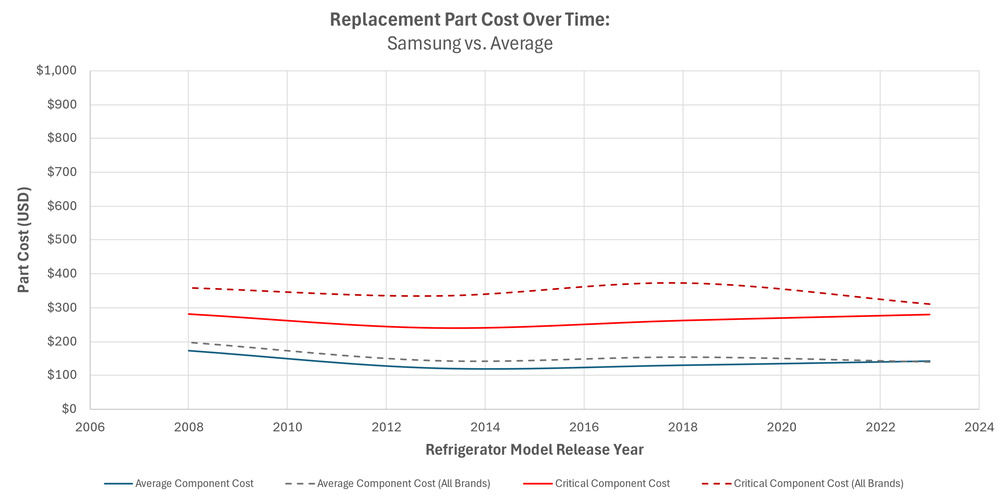

Samsung:

Samsung, as with their authorized service coverage, faces severe issues with their parts availability. Their early life availability hovers below 30%, which is problematic for in-warranty repairs and can lead to massively increased downtime. Even their mid-life models aren't well-supported, with only 40% of parts available amongst our tested suppliers. Availability improves to baseline for late-life and EOL models; however, the weak early-life support can make it difficult to maintain the appliance into later years.

Conversely, Samsung's part costs are the lowest among the brands tested, making repair an economical option at any stage of the appliance's life. Samsung also reuses more components across models than any other brand. The upside is that common parts such as thermistors and fan motors remain in production for many years. The downside is that because so many units depend on them, these parts are often in high demand and can be harder to source quickly, hence the lower overall availability.

In summary, Whirlpool, Frigidaire, and GE offer the strongest parts support with good availability from early life through to end-of-life and prices that keep repairs economical. LG sits squarely in the middle of the pack, with parts somewhat harder to source across the lifecycle but low prices that give their refrigerators good long-term supportability. Bosch supports newer models well but drops off sharply as units age, with higher part prices making long-term repairs less practical. Samsung trails with the weakest availability, especially early on, and while its heavy part reuse keeps components in production, high demand makes them harder to secure quickly.

As with the service coverage test, this study represents only a static point in time. For a more comprehensive understanding of how parts availability differs between brands, the exercise should be repeated regularly to capture trends, since availability can shift from week to week. We plan to continue collecting data across more brands and models in order to build a broader and more complete assessment of long-term parts support.

Refrigerator Reliability Is Difficult to Predict

Reliability engineering is a well-established field; however, it's heavily dependent on historical data across a product's lifecycle. Predicting reliability, ideally, is achieved by analyzing long-term data over a product's life, but this data is nearly impossible to find. While manufacturers collect and closely monitor why their products are failing, this data isn't made publicly available. Naturally, sharing this information with the consumer would make them less likely to purchase their product.

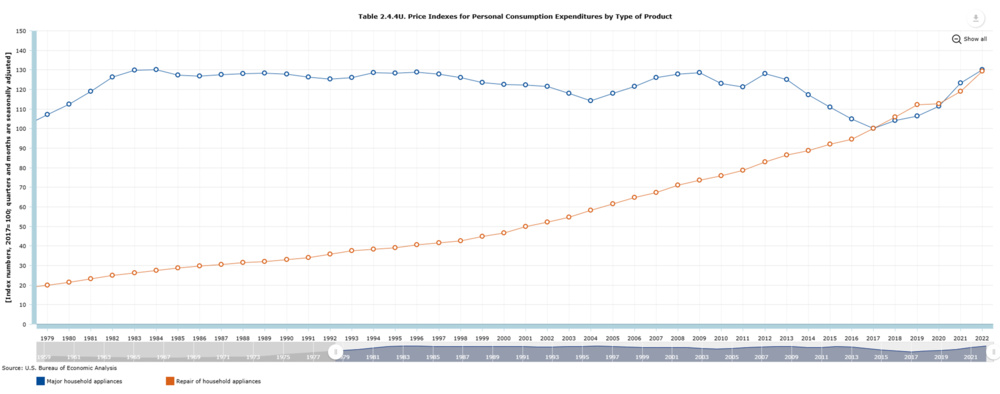

Without hypothesizing around planned obsolescence, a simpler explanation would be the cost of appliance repair that has skyrocketed in recent years.

As repair costs reach or exceed the price of purchasing a new refrigerator, many people understandably forego repair in favour of a brand new, more efficient appliance. This ultimately leads to there being fewer modern refrigerators in service, limiting the amount of historical data available.

The Cyclical Nature of Appliance Reliability

Further compounding the confusion for consumers is the cyclical nature of appliance reliability. Refrigerator models are redesigned and released frequently. As we've seen, some manufacturers do reuse proven components across designs, but the reliability of a single component cannot guarantee the reliability of the appliance as a whole. And, as energy efficiency regulations are regularly updated with stricter requirements, manufacturers are forced to overhaul designs and use newer, more efficient components.

While brands like Samsung (ice makers) and LG (linear compressors) have gotten bad reputations for serious failures in recent years, resulting in extensive repairs and class-action lawsuits, no single manufacturer is immune to design flaws. Whirpool has faced evaporator issues in French door models, Frigidaire has had recurring ice maker problems, and GE has been linked to sealed-system failures, as some examples. What consumers also can't see are the internal service bulletins issued to technicians, which quietly track recurring problems without publicity.

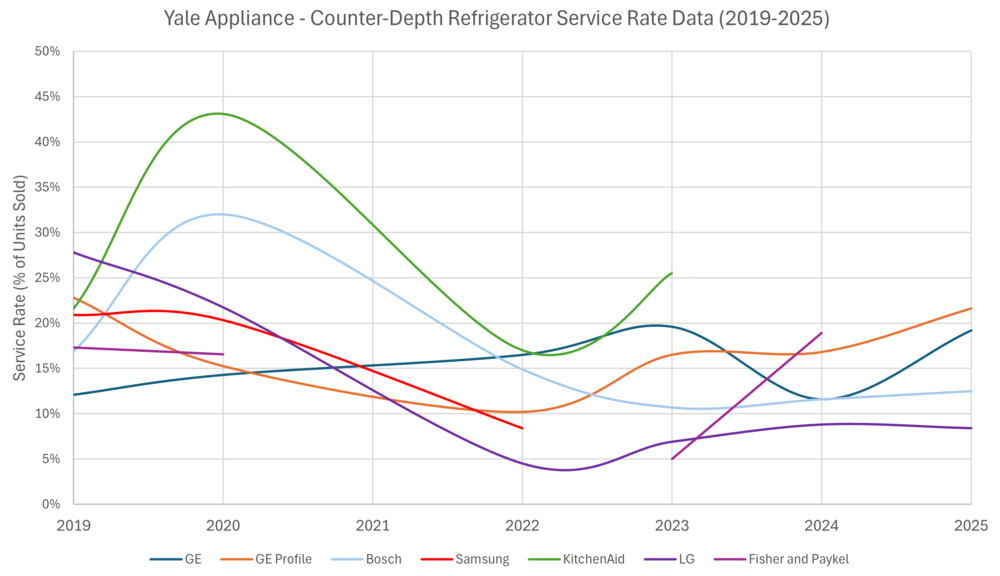

The point is that problems can arise and get mopped up from year to year. One of the only credible, publicly available sources for reliability over time comes from Yale Appliance, who both sell and service refrigerators. They track the number of service calls vs. number of appliances sold every year, which we've graphed below:

This graph confirms that appliance reliability isn't a linear trend over time. Service rates fluctuate from year to year, and no brand is consistently trouble-free. The takeaway is that consumers rarely get to see concrete, transparent information and data on which to base their decision when choosing a reliable refrigerator.

The Limits of Accelerated Life Testing in Refrigerators

In the absence of such data, accelerated life testing (ALT) can simulate a product's lifecycle in a much shorter period; this is an effective approach in many products. For example, rapid charge-cycling a smartphone battery, or non-stop loads in a washing machine, can simulate years of use in a matter of weeks or months.

Refrigerators, however, are already designed to run 24/7 for multiple years. There are limited ways to "cycle" them harder without introducing conditions that don't reflect real use. Existing studies in the field include accelerating the life of components like door hinges, but that's not really a top complaint people have when discussing their refrigerator breaking down.

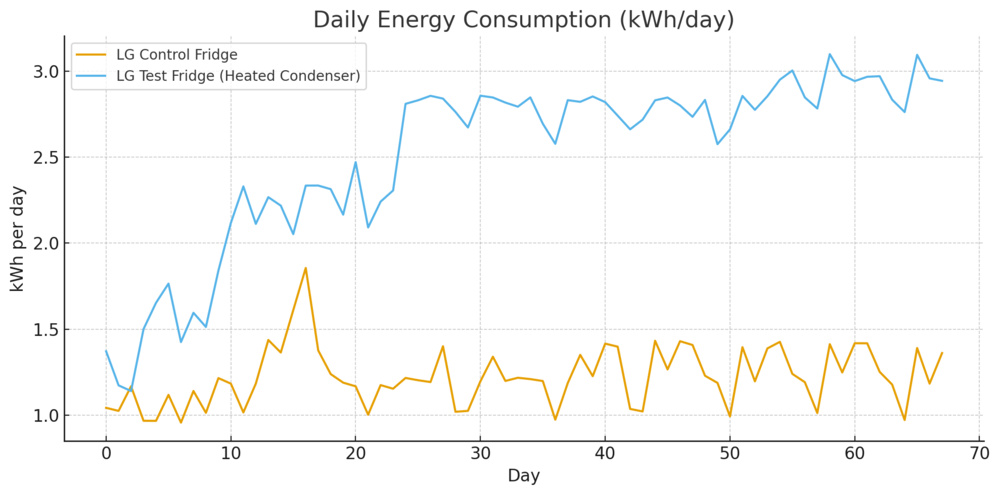

We did attempt accelerated life testing in our lab by accelerating the duty cycle of a compressor by heating the condenser coil and making the compressor work longer to keep the inside of the refrigerator cold. We also added automatic door openers to simulate a user opening the door multiple times a day.

Unfortunately, compared to our control unit compressor, which ran 70% of the time on average, we were only able to increase our duty cycle to 95%. This means that simulating 10 years of use, for example, would still take roughly seven to eight years in our lab, by which point our test units would be nearing obsolescence. Coupled with what we learned at Fred's Appliance Academy, that sealed-system failures such as compressors represent less than 2% of annual service calls, the return on an ALT program is poor. In short, refrigerators already operate nearly continuously, leaving little headroom to accelerate testing, and because the most common failure points in new models are unpredictable, accelerated life testing cannot provide a reliable estimate of real-world performance.

Practical Reliability Considerations When Buying a New Refrigerator

As we've seen, predicting the reliability of a refrigerator via traditional, data-driven means remains mostly intangible. Manufacturers don't offer data on long-term failure rates, accelerated life testing doesn't work well for refrigerators, and consumers are left with little concrete information on how long a model will last.

With that in mind, through what we have learned while investigating the topic, there are some practical choices you can make when considering a new refrigerator to reduce your chances of costly failures down the line.

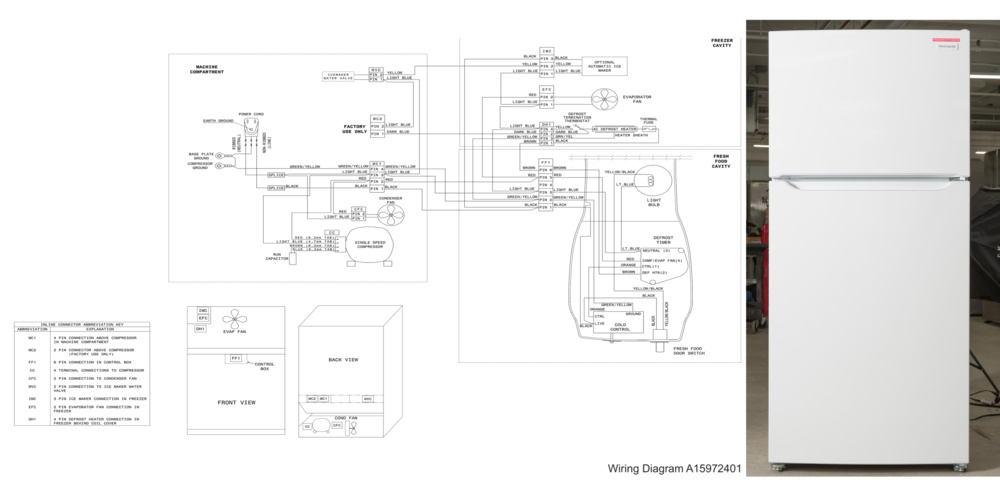

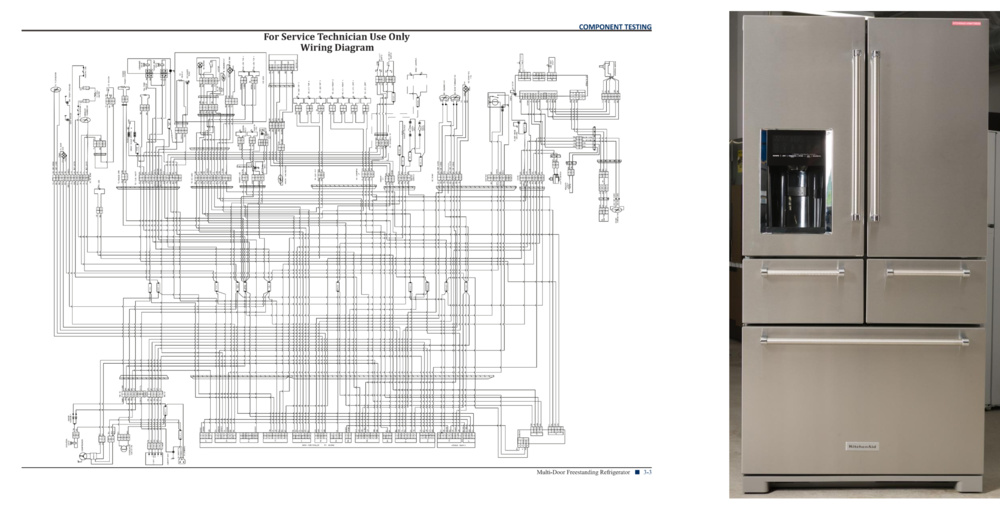

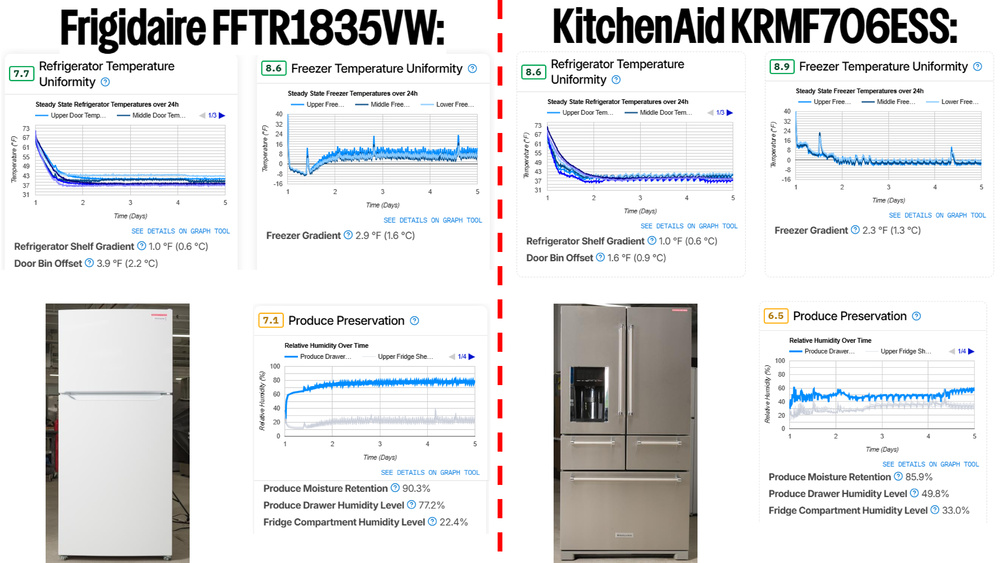

1. Avoid added features unless you absolutely need them. While refrigerators are more feature-loaded than ever, there still exist models available for purchase today that forego a lot of the complexity seen in modern designs. Take, for example, the wiring diagram of the Frigidaire FFTR1835VW, a basic top-freezer model, in comparison to the KitchenAid KRMF706ESS, a higher-end five-door model with through-door ice and water access and adjustable, temperature-controlled zones:

While we can't at this point say if one design is more reliable than the other, it's not unreasonable to assume that adding more components introduces more potential failure modes. While the added features are convenient and do offer some improvements to performance, at the end of the day, both of these models work perfectly fine for their core functionality of keeping food cold.

2. If you need an ice maker, choose one located in the freezer. Ice makers located in the refrigerator compartment require additional cooling to create a freezing microclimate in a comparatively warmer environment. If possible, forego through-door ice and water access, as this adds more complexity via additional seals and motors.

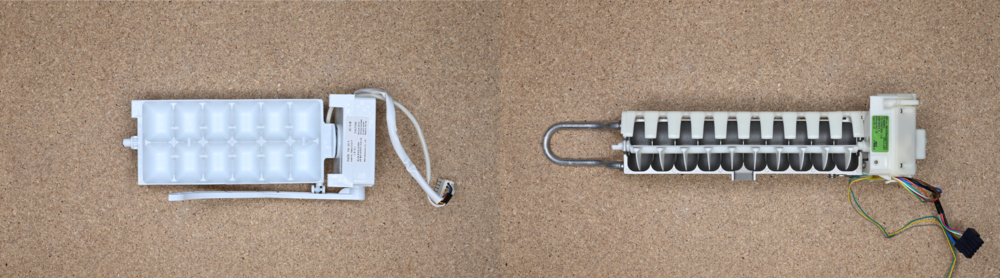

3. Consider the type of ice maker inside the refrigerator. Many refrigerators today incorporate twist-tray ice makers, which rely on flexing the plastic tray to release ice. The plastic is also subject to high levels of thermal cycling over time as water freezes into ice. This combination of thermal cycling and flexing will inherently fatigue the plastic tray, raising the risk of it breaking over time. Conversely, some models still offer ejector-style ice makers, which use a metal mold and a small heating element to release the ice before a small arm "rakes" it out of the mold. While slightly less efficient due to the heating element, the metal mold and smaller loads on plastic components make them more durable.

4. If possible, consider waiting until a refrigerator model has been on the market for a year or two before purchasing. Early adopters can face a higher risk since the potential failures of new designs aren't yet known. By choosing a model with a bit of time on the market, you may benefit from more publicly available feedback and service data that can help you avoid a failure-prone model.

5. Do your research before you buy. This is sound advice for any product, but especially for a higher upfront investment like a refrigerator. Along with looking for authorized service coverage and parts availability, as we've discussed, carefully read the warranty for the refrigerator you're considering. Warranties can differ between brands and models in terms of what parts they cover and how long they're covered for.

Conclusion

Choosing a long-lasting refrigerator is difficult to predict. The cyclical nature of appliance reliability, frequent redesigns, and new models, coupled with the rising cost of repair, which takes models out of service faster, makes long-term reliability data difficult to gain. Accelerated life testing, which is an effective way to predict the reliability of many products, isn't nearly as effective in an appliance that’s designed to run continuously for years on end.

As such, we've determined that it's better to shop for support before you buy. Strong service coverage and steady parts availability can make the difference between a product you replace after a few years, versus one that you can maintain during and beyond its service life. For buyers, the most reliable choice is the one backed by support.