A refrigerator is one of the hardest-working appliances money can buy. Nothing else in your home is expected to run constantly while juggling a pretty wide set of elements: cold to sub-zero temperatures, virtually zero downtime, and sometimes providing running water and ice on demand, neither of which plays nicely with most consumer electronics. And yet, despite these sky-high expectations, their operating principles haven't exactly shifted much in the century-plus that they've been around. So, how exactly does a refrigerator work?

Test results

The Basics of Refrigeration

Any given refrigerator can basically be isolated into three core groups of components.

- The main refrigerator and freezer cabinets

- Electrical componentry for primary and various ancillary components (control boards, lighting, fan motors, etc.)

- The sealed system, or the passages through which the refrigerant passes

That last one is the beating heart of the fridge. It is, as the name implies, a completely closed loop through which refrigerant moves and makes the fridge work.

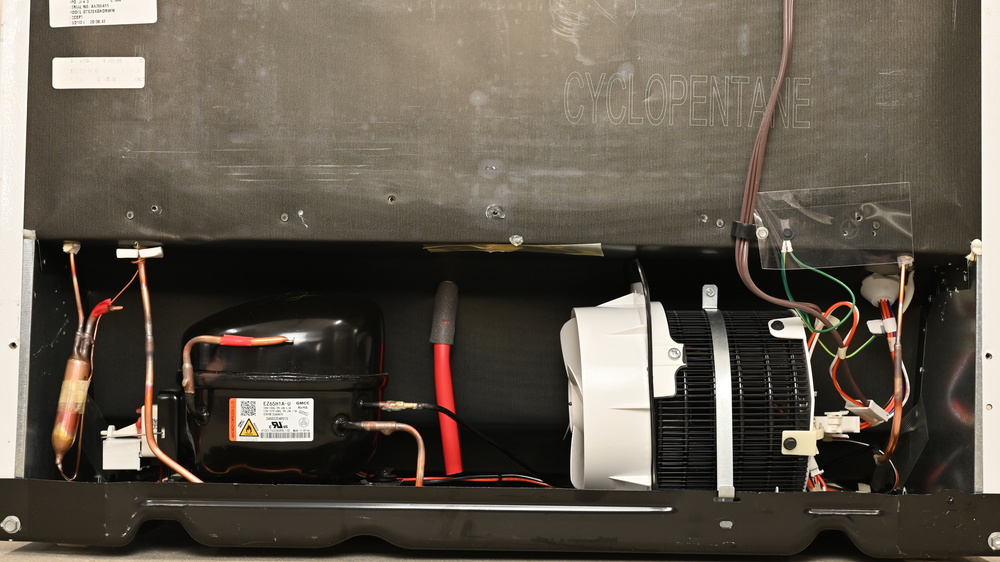

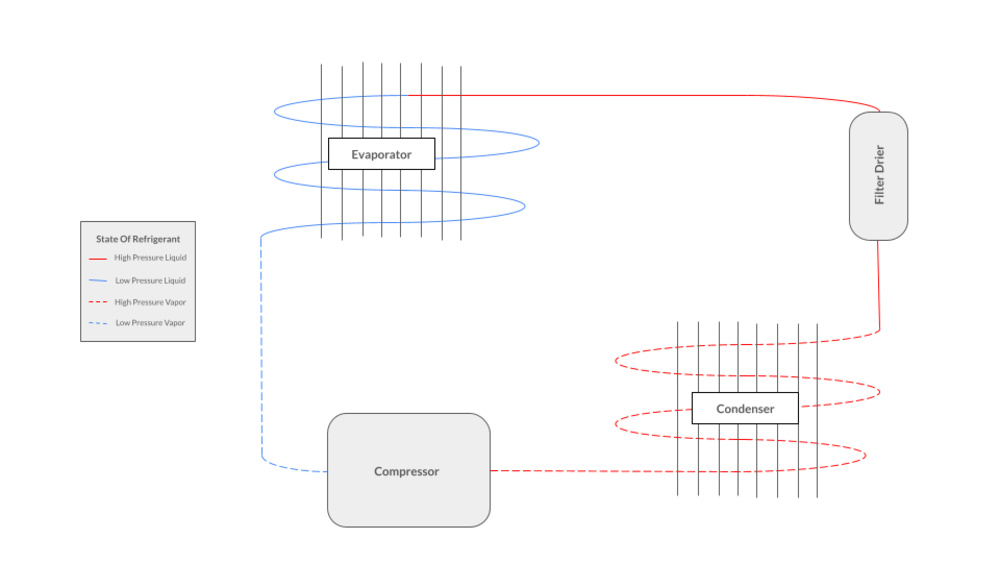

The Sealed System

We'll start tracking the refrigerant's journey as it's pumped out of the compressor. It passes through the narrow opening of the discharge tubing before entering the condenser coil as a hot, high-pressure gas. Air passing over the large surface area of the condenser coil cools the high-pressure refrigerant, and at the risk of stating the obvious, allows the high-pressure gas to condense into a liquid. It then passes through the filter drier, which is meant to remove any impurities like debris or moisture from the refrigerant before it passes through the capillary tube and into the evaporator coil, which is where the actual cooling occurs.

The tubing of the evaporator coil has a much larger internal volume than most of the systems' discharge tubing, which lowers the pressure of the liquid refrigerant. This now low-pressure liquid moves through the evaporator coil and absorbs heat from food stored inside the freezer or fridge compartments, cooling the air inside the compartment. This heat absorption causes the low-pressure liquid to gradually re-evaporate into a low-pressure vapor by the time it exits the evaporator coil, re-enters the compressor, and begins the cycle anew. Here, we can also take a look at some of the separate components inside the sealed system and how their design might vary in different fridges.

Compressor

The compressor's job in a fridge is to pressurize the low-pressure refrigerant into a high-pressure gas before it can make its way over to the condenser coil. Compressors can be lumped into two main categories: fixed-speed and inverter-type. A fixed-speed unit is exactly what it says on the tin: the compressor operates at a set operating speed consistently. Meanwhile, an inverter compressor, popular on pricier and newer fridges, can vary its operating speed depending on the required cooling needs inside the cabinets. This drastically lowers day-to-day energy consumption. This isn't the only factor influencing a fridge's energy consumption (check your fridge door seals, folks!), but it can play a big part in that equation, and it's certainly worth considering an inverter fridge if energy costs are a significant personal concern. With that said, it's worth noting that fixed-speed compressors are of a much simpler design than inverter units, with no delicate control mechanisms that could fail. That's not to say that simplicity is a guarantee of reliability, but a fixed-speed compressor does have fewer potential failure points.

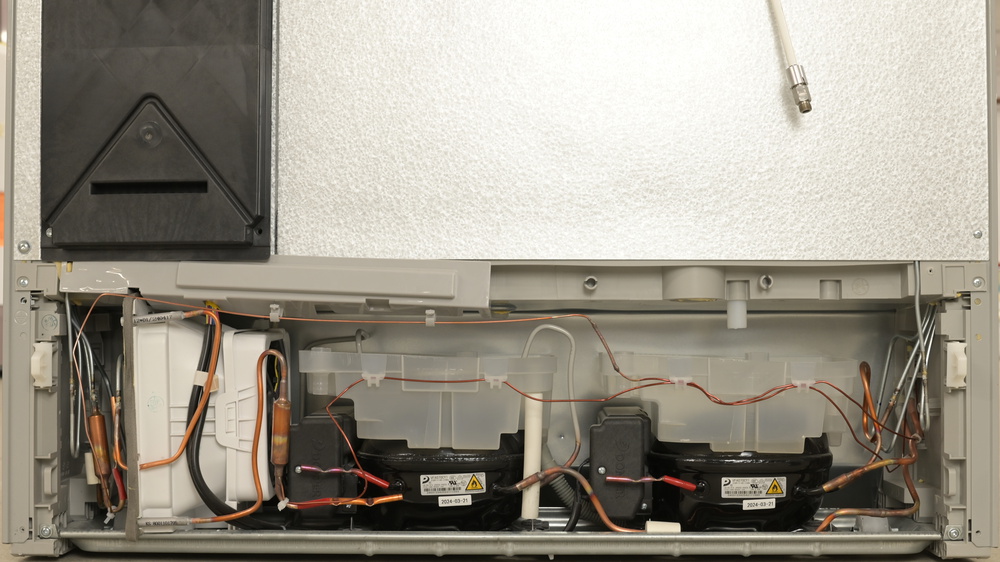

While most refrigerators on the market use a single compressor to pump refrigerant through the refrigerator and freezer cabinets, commercial and super-high-end household units from brands like Sub-Zero run separate compressors for each cabinet. To date, we've only tested a single refrigerator with this arrangement, that being the Bosch 800 Series B36CT80SNS. This design obviously adds cost and complexity, but it can pay dividends. With separate compressors, the load is distributed across separate units, meaning that each compressor only needs to work half as hard, theoretically increasing its lifespan. There's also the cooling consistency aspect, as separate compressors allow for more precise temperature regulation in each section of the unit. Then there's the redundancy aspect: if one compressor fails, it won't require a repair to the entire sealed system, just the loop that experienced a failure.

Condenser Coil

A condenser coil dissipates heat from hot refrigerant passing through the system, but the actual mechanism and placement of this component will vary. If the movement of refrigerant is the beating heart of a refrigerator, then we can stretch this tortured metaphor a little further and call the circulation of air through the system its arteries and veins. You've got a few different types on the market. Most modern fridges use a dynamically cooled condenser design, where air is circulated across the coil by a series of built-in fans. This obviously promotes far more consistent temperatures throughout the appliance compared to the static-cooled systems found in early fridges from the mid-20th century: in those models, air circulation over the condenser coil in the unit is driven mainly by convection, with colder, denser air sitting lower in the cabinets, while warmer air rises to the top, closer to the condenser coil. This static-cooled condenser is a hugely energy-efficient design, but comes with a whole heap of downsides, most notably drastically higher temperatures in the upper regions of the fridge, substantial frost buildup that needs to be cleared out regularly, and the need for considerable clearance around the fridge to ensure strong airflow moving over the coils.

Dynamically cooled condensers still need a fair amount of clearance to operate properly, but significantly less than the static-cooled units. Since they're also fairly exposed, usually being located at the back of most fridges, they can be clogged by dust or pet hair and should be cleaned periodically. You should be careful not to overload the fridge too, especially near the top of the unit. This is usually where the cold air is circulated from, which can result in some items getting frozen and blocking the flow of air through the rest of the cabinet.

Lastly, there are skin condensers, where the condenser coils are built into the walls of the unit. The allure of this design is pretty simple: there are virtually no regular maintenance requirements since the condenser coils cannot become dirty.

Unfortunately, there's a pretty long list of disadvantages too: heat transfer through the walls of the cabinets is limited, which in turn inhibits the overall efficacy of the condenser coil. Since heat is trapped on the inside of the cabinet walls, it also results in the outside of the unit becoming very hot, especially if you were to dump a whole heap of warm leftovers into the fridge, for instance. As a result, they aren't great for narrower niches in kitchens. Then there's the serviceability aspect: if the condenser ever gets damaged or clogged, there's effectively no way to access it without disassembling the entire fridge.

Evaporator Coil

Most fridges on the market utilize a single evaporator coil located inside the freezer section. This design is efficient and relatively simple, but not necessarily ideal from a food preservation perspective. In these sorts of designs, cold air flows between the fridge and freezer, pulling moisture out of the fridge and drying out the food inside. This can be noticed in things like delicate greens wilting within a few days.

|

|

Twin evaporator coils are becoming an increasingly popular design feature found on higher-end fridges. The promise is appealing: with separate evaporator loops, air isn't shared across the refrigerator and freezer cabinets. This limits odor transference, so your ice cubes won't come out smelling like rotisserie chicken. Better yet, separate evaporators allow for tailored humidity levels inside the freezer and fridge cabinets. A dual evaporator can provide high humidity in the fridge compartment to bolster food preservation and lower humidity in the freezer to inhibit frost buildup.

The Defrost Cycle

On that note, frost buildup on the evaporator coil triggers another important function in most fridges: the defrost cycle. To summarize, there are a few different defrost systems. Manual defrost systems are common on older fridges and upright freezers and are found on virtually all chest freezers. With these systems, you'll need to pull all food from the cabinet and clear away the ice buildup around the coils to restore their efficacy, being very careful not to damage the evaporator coils. This is obviously a bit of a hassle, but it also provides the best overall cooling performance, as temperatures inside the freezer cabinet always remain at a consistent level.

Most modern fridges use automatic defrost systems, though the mechanism through which they operate will vary too. Your garden-variety automatic defrost system will usually include three main components:

- A timer to maintain a set number of defrost cycles per day

- A mechanical or electric thermostat to stop the defrost cycle once the desired temperature is reached

- A heater to actually defrost the evaporator coils

These systems aren't perfect, however: overly frequent defrost cycles can have a negative impact on the quality of frozen food and drive up energy costs since the compressor will need to work harder to regularly bring the freezer cabinet back down to temperature. Adaptive defrost systems will go a step further and take into account a wide variety of other parameters, including airflow on the return and discharge sides of the evaporator coil, as well as the pressure of refrigerant moving through the system. These added parameters are meant to ensure that the defrost cycle runs only when the evaporator is iced over, and not when it's just scheduled to run.

If you're interested in seeing a more in-depth look at defrost systems, check out our article on the topic.

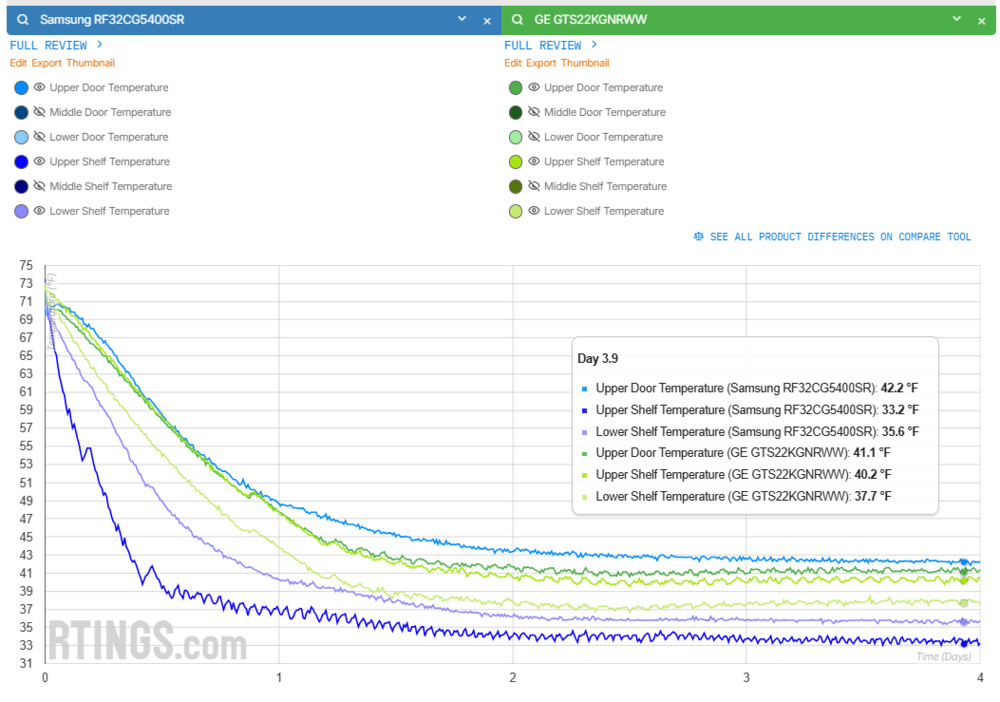

Temperature

Two main factors influence how long food lasts in your fridge. The first, temperature, is effectively a freebie: it's not exactly a secret that food stored at 40 °F (4 °C ) or less lasts much longer than food left out at room temperature. The specifics, however, can vary depending on the fridge type. In a top freezer unit, with cold air coming from the evaporator at the top freezer compartment, the coldest place in the refrigerator cabinet is going to be the top shelf and, in some cases, the upper door bins.

In contrast, a French door model, with its evaporator placed within the lower freezer compartment, will generally have a colder lower section of the cabinet. Cold air is denser and falls to the bottom of the cabinet, which further helps keep this area cool. In any case, you'll want to avoid placing items like eggs or berries in the very coldest areas of the fridge, as they can freeze in those spots.

Additionally, most refrigerators, regardless of design, tend to suffer from a common issue: the door bins tend to be warmer than the rest of the cabinet. This isn't overly surprising from a pure physics standpoint: evaporator coils are generally placed at the back of the fridge, the farthest they can be from the door bins. While refrigerator door bins are traditionally advertised as the best spot to place items like jugs of milk, this is generally the warmest (and therefore worst) spot to place these sorts of temperature-sensitive items. Manufacturers attempt to circumvent this by directing airflow to these areas. The LG LRFLC2706S is a clear example of this. It has an (admittedly small) aperture at the top of the front of the cabinet to orient cool air towards the door bins.

Humidity

As far as fridge performance goes, the other main factor in food preservation is humidity. Delicate produce like spinach, lettuce, or celery has a high moisture content. As produce evaporates this moisture into the surrounding environment, it loses its characteristic 'snap' and takes on a wilted, mushy consistency. As the name implies, crisper drawers keep these sorts of foodstuffs crisp by maintaining a humid environment. Crucially, there are a few ways of achieving this goal.

| Refrigerator | Style | Evaporator Configuration | Produce Drawer Humidity Level | Fridge Compartment Humidity Level | Produce Moisture Retention |

|---|---|---|---|---|---|

| Bosch 500 Series B36FD52SNS | French Door | Single Evaporator | 93.7% | 15.7% | 97.2% |

| GE Profile PGE29BYTFS | French Door | Dual Evaporator | 73.3% | 60.8% | 87.4% |

| Frigidaire FFTR1835VW | Top Freezer | Single Evaporator | 77.2% | 22.4% | 90.3% |

| Whirlpool WRS321SDHZ | Side By Side | Single Evaporator | 71.7% | 18.8% | 84.5% |

| KitchenAid KRSC703HPS | Side By Side | Dual Evaporator | 80.3% | 43.8% | 92.9% |

The first is via separate evaporators for the fridge and freezer compartments. As mentioned earlier, humidity plays a diametrically opposed role in either section of a household refrigerator: it's desirable to maintain a high level of ambient moisture to prolong the shelf life of produce in the refrigerator, but you'll want the opposite in the freezer to limit frost buildup on the evaporator coils, which compromise its ability to transfer heat from the system. As shown above, dual evaporator units are far better at maintaining a humid environment outside of the crisper drawers, which will extend the shelf life of delicate greens that don't fit in your crisper drawers.

Of course, that doesn't mean that single evaporator models are incapable of keeping produce fresh: the Bosch 500 Series B36FD52SNS clearly illustrates the other path manufacturers can take. Its single evaporator design results in a very dry main refrigerator cabinet, yet its crisper drawer is able to sustain some of the highest humidity levels we observed while in testing. How? Simple: its crisper drawer can be virtually sealed, effectively isolating the compartment from the rest of the cabinet.

Ice Makers

Ice makers are a highly popular (some would say indispensable) feature in many a modern fridge. Regardless of where they're placed in a fridge, their method of operation is pretty consistent and works according to a loose three-step process:

- Freeze

- Harvest

- Fill

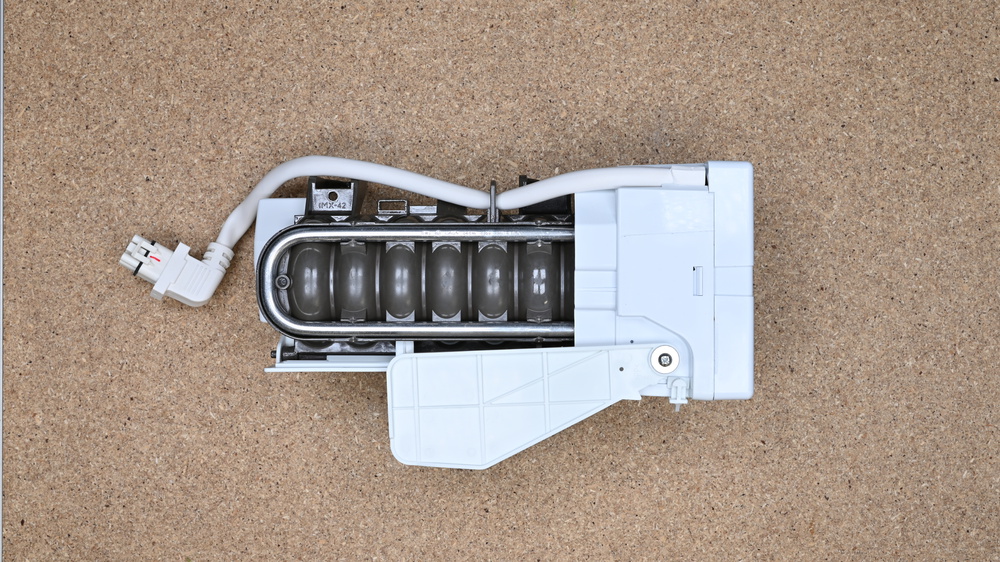

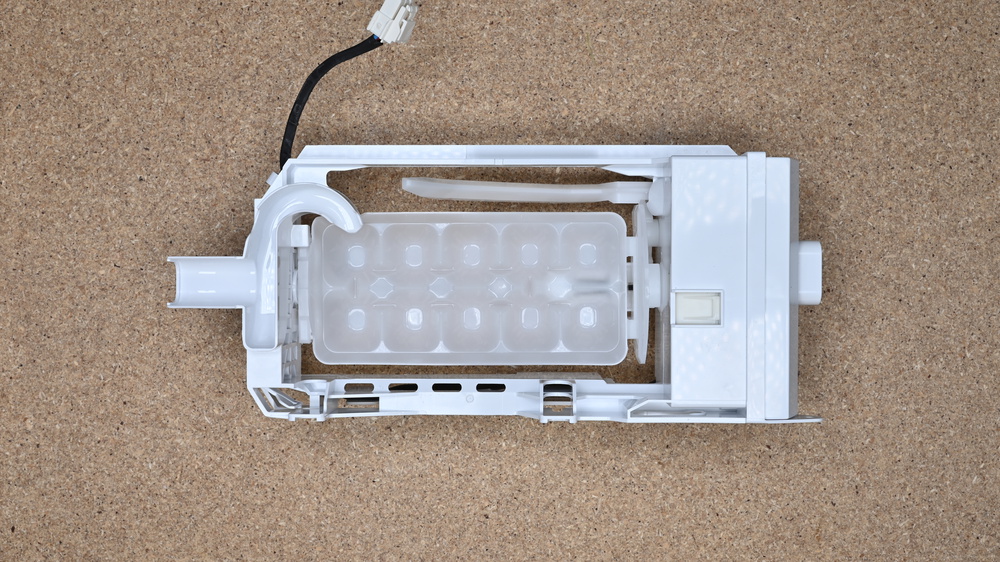

In the first freezing stage, water is piped into the ice maker mold from lines running around the fridge through a valve that stays open just long enough to fill the mold. Once the thermostat inside has determined that the water has reached freezing temperature, the ice maker can now harvest the ice. This is where you'd see the biggest difference in terms of ice maker design. In brief, an ejector-style model will have a metal mold that's gently heated to loosen the ice before it's scooped out, while a twist-tray model works exactly how it sounds: the mold, being made of thin plastic, can be twisted and deformed to pop the formed ice cubes out. From here, things are quiet until you've emptied the ice tray, which triggers the fill phase, at which point the water valve circuit closes again, reopening the water valve and restarting the entire process.

|

|

Check out our full article on ice makers if you want to see a more in-depth look at their method of operation and differences in design.

Conclusion

We hope this rundown on refrigerator design and its impact on general performance was useful. If you're shopping for a refrigerator and want to know a bit more about the pros and cons of each type, go ahead and check out our article on refrigerator types as well as our recommendations for the best refrigerators and best French door models. Or, if you're still figuring out what'll fit in your kitchen, check out Refrigerator Sizes: How to Find the Perfect Fit.